CNC Solutions for Wind Turbine Manufacturers

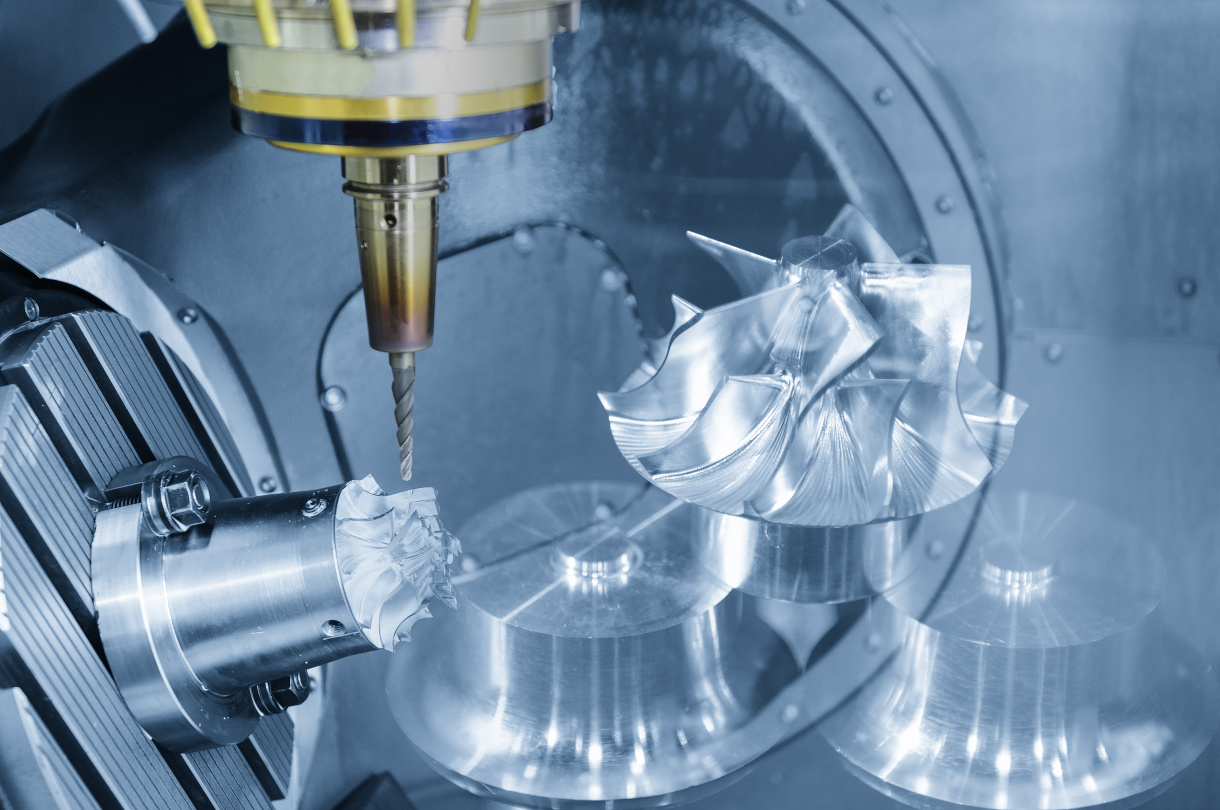

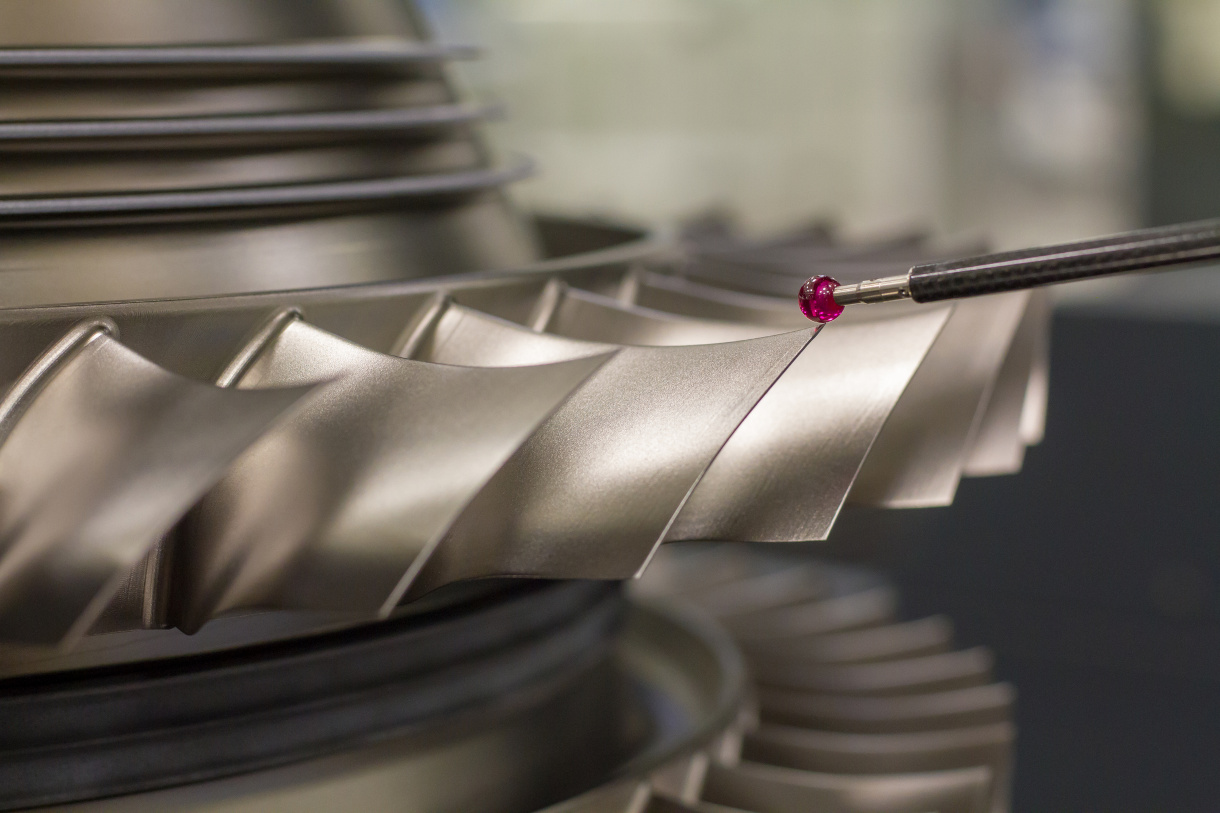

Machine tools play a crucial role in producing precision finished parts that keep blades spinning and power flowing from wind turbine equipment. We offer comprehensive CNC solutions for manufacturers machining components for the fast-growing wind energy industry.

ROI Calculator

See how quickly you can expect our custom-engineered and automated CNC machines to deliver on your investment.

PROVEN RESULTS

Delivering Higher Job Capacity and No More Outsourcing

Read how this job shop gradually implemented our 5-axis technology and automation systems to enable strategic business growth.