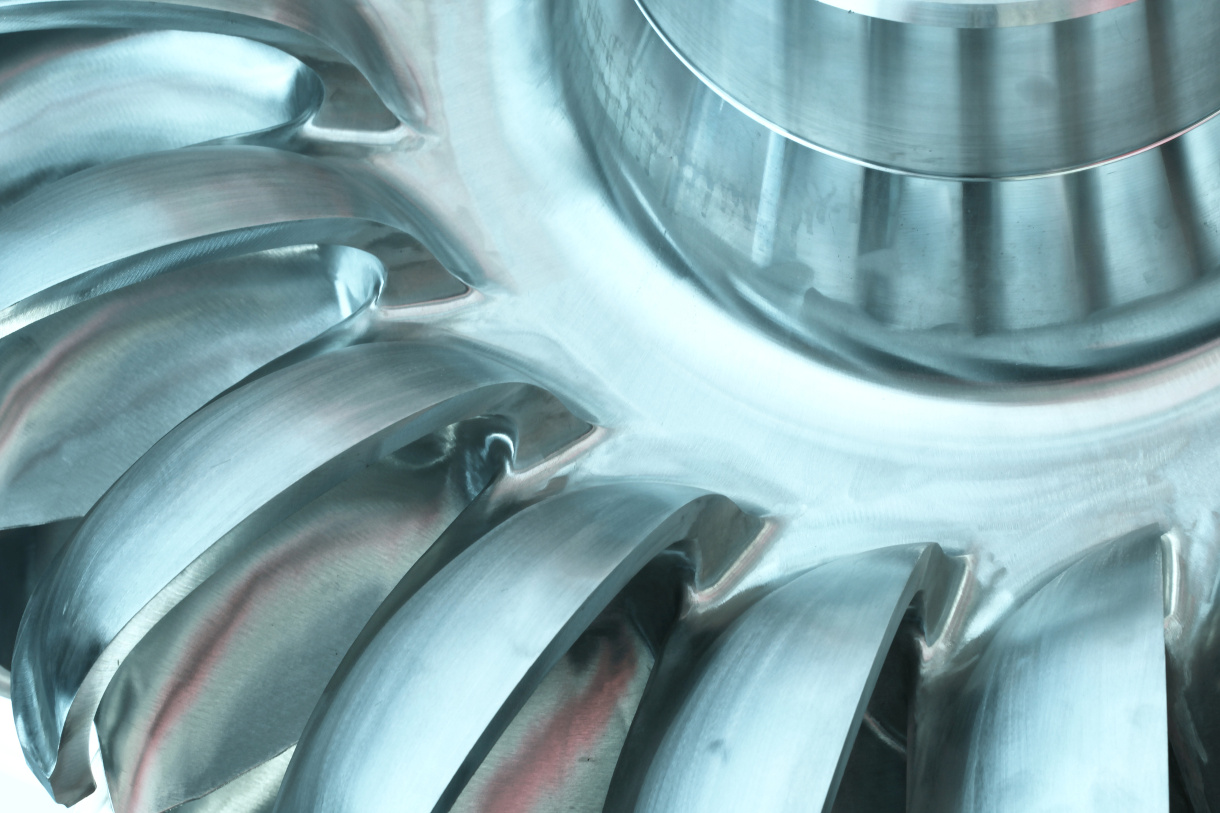

Machining Solutions for Hydroelectric Components

We offer the precision machining solutions needed to produce high-quality parts for hydroelectric power generation. Our engineers lead your team through the end-to-end process of designing and integrating systems optimized for applications.

ROI Calculator

See how quickly you can expect our custom-engineered and automated CNC machines to deliver on your investment.

PROVEN RESULTS

Cobot Enables Wire EDM Shop to Perform More Jobs

DP Diamond Products specializes in wire electrical discharge machining (EDM) for a variety of industries.