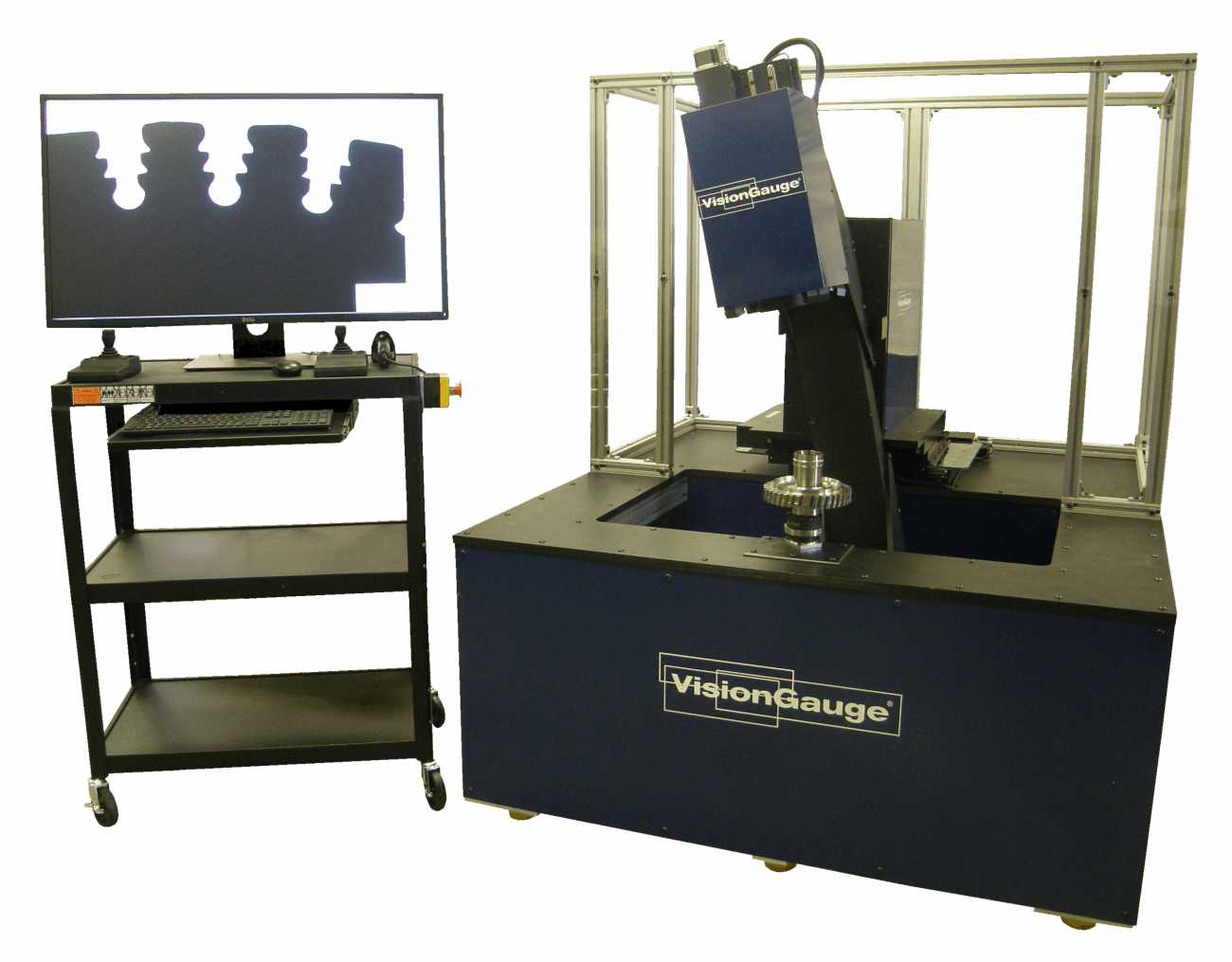

The VisionGauge® Disk Inspection & Measurement System is the ideal solution for the inspection & measurement of slots in turbine disks, both large & small.

Automatically carry out 100% inspection, to very high-accuracy, and collect operator-independent results, directly on the shop floor.