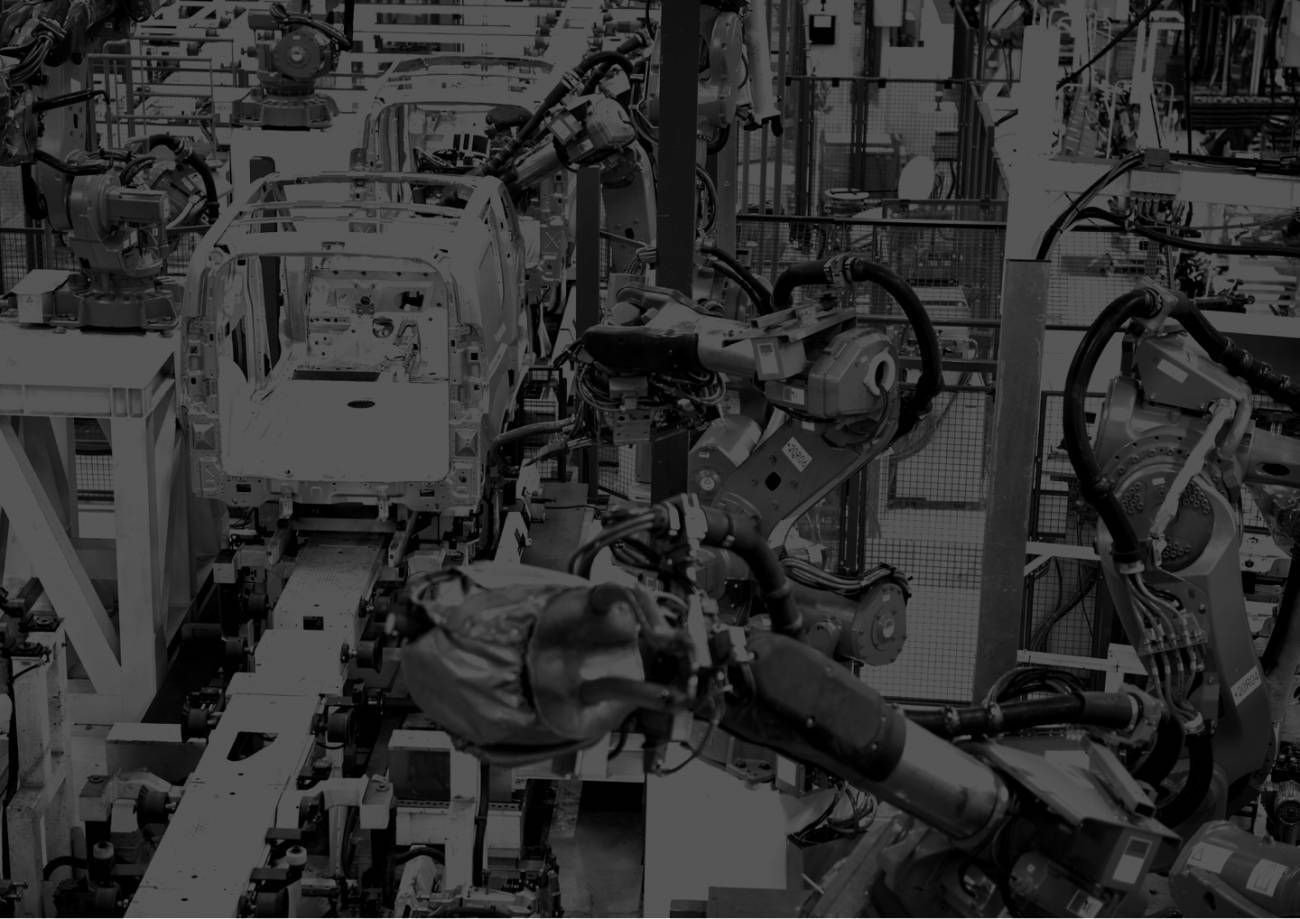

Automation

Advanced automation solutions from Methods improve production quality and efficiency while lowering operating costs and maximizing ROI for manufacturers.

Request

Information

Get Maximum Value From Automated Machining Equipment

Automated Solutions Improve Productivity and Lower Operating Costs

Methods’ engineering team designs highly customized automation solutions to create new efficiencies and produce the most value and ROI for your manufacturing operations. We strategically integrate automation into your machining processes to ensure your Methods solution delivers immediate success and profitability through machine tending, gauging, and other secondary operations.

Automation Designed for Your Specific Needs

Nothing about automation is off-the-shelf, and no two machine shops are exactly alike. That’s why our dedicated automation experts immerse themselves in your manufacturing environment to understand your unique challenges before designing automated solutions that focus on your specific business goals. The result creates opportunities for your business to increase capacity, revenue, and profit margins.

Supported by Experts from Beginning to End

Our team of automation experts collaborates with you from initial planning and selecting the right machines to work-process design and application engineering, to the final on-site installation and proof of concept and capability.

Located across the U.S., our comprehensive team of design engineers, control engineers, fluid engineers, integration/assembly engineers, field service/installation engineers, electrical/mechanical engineers, and machinists handle every phase of your automated machine implementation. Methods provides ongoing, highly responsive service and support to ensure our machining solutions always perform and deliver results.

Automation Platforms

- Methods Automation Plus-K

- Methods Automation Plus Big-K

- Methods Automation Plus-E

- RoboJob

- JobShop Cell Collaborative