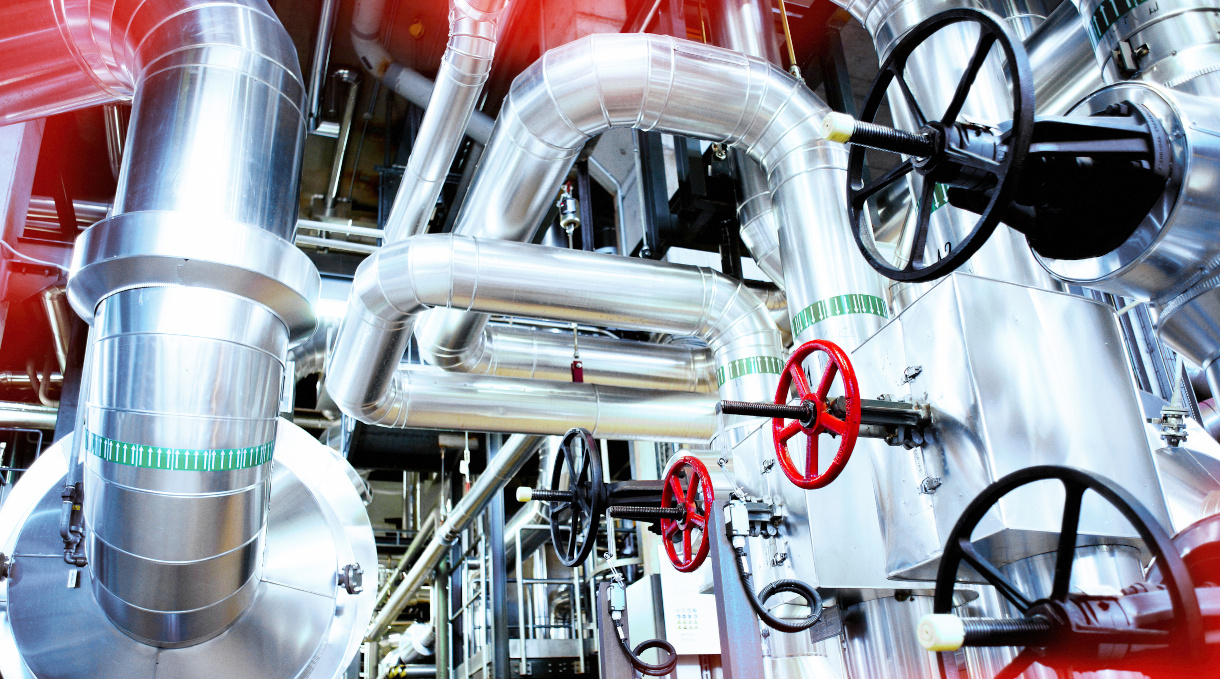

CNC Solutions for Petroleum Refining Operations

We supply the world’s best CNC machine solutions and combine them with advanced engineering services to deliver reliable and consistent production for precision manufacturers in the refining industry.

ROI Calculator

See how quickly you can expect our custom-engineered and automated CNC machines to deliver on your investment.

PROVEN RESULTS

Leveraging Automation for Strategic Business Growth

After growing with Methods to implement 5-axis, and multitasking technology, Operose founder Tyler Stilson wanted to increase his throughput with automation.

Our 3- and 5- axis vertical machining centers are made with high-quality builder components designed to provide speed, accuracy, precision, and stability.

Our 3- and 5- axis vertical machining centers are made with high-quality builder components designed to provide speed, accuracy, precision, and stability.