51

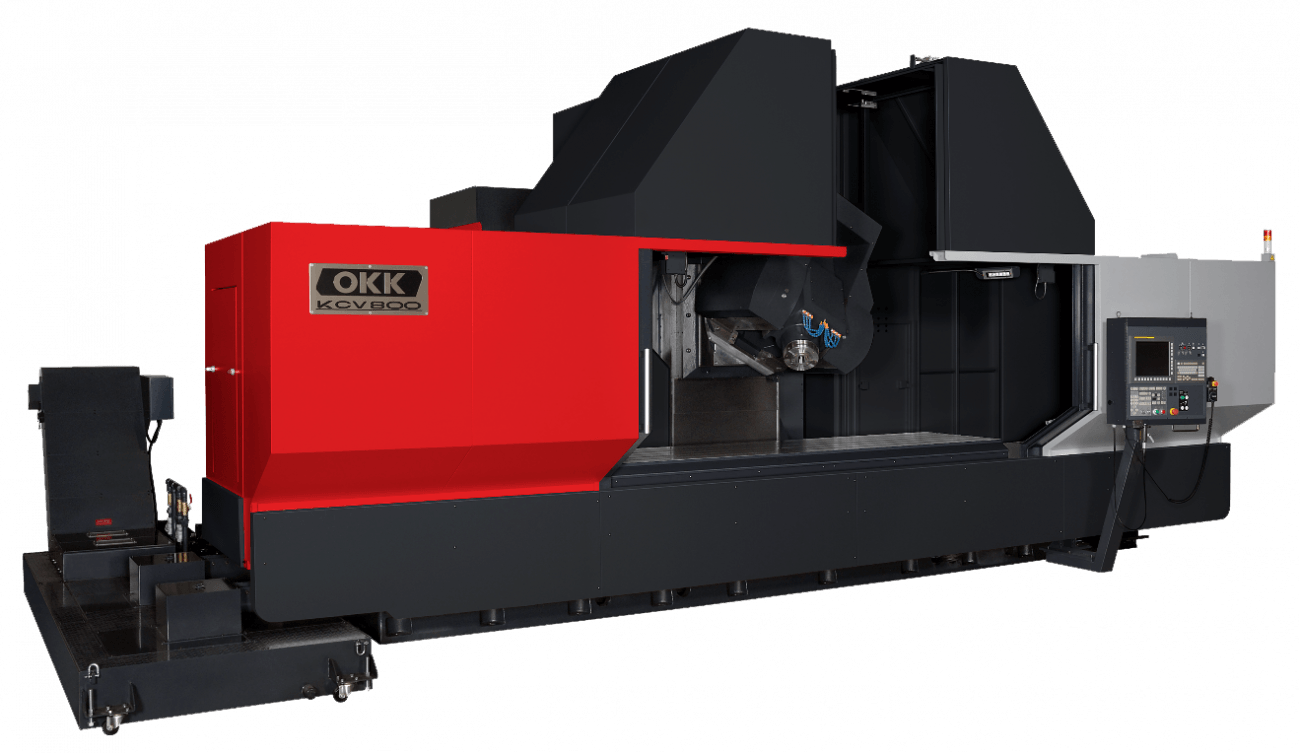

OKK

KCV800-5AX

*Availability of machines is based on region. Contact your local Methods office to learn more.

The flexible design of the KCV 5AX Series meets your changing needs from short-term projects to production manufacturing of Large work pieces. Extreme stability and speed provide both high accuracy and productivity, without sacrificing easy accessibility and rigidity. From Aircraft parts to Large LCD components, its flexible design meets the users needs.

Request Information

Or call 1-877-668-4262

Product Details

Features & Benefits

- High efficiency 5-axis operation with spindle tilt/swivel system

- Space saving design for economical use of floor space

- Highly rigid machine structure produces highly accurate processing

- Thorough measures to control thermal displacement

- Operator friendly traversing column

- Highly rigid high-speed feed systems

- Core chilled ball screws

- Double anchored support system

- Excellent chip evacuation with standard 4 chip auger and lift-up conveyer

Technical Data

Travel

- X-Axis Travel

- 120.1" (3050mm)

- Y-Axis Travel

- 32.3" (820mm)

- Z-Axis Travel

- 28.4" (720mm)

- A/B Axis Travel

- ‐40° to +40°

- Tan;e Tp[ to Spindle Nose

- 7.9" - 36.2" (200mm - 920mm)

Table

- Table Work Surface Area

- 129.9" x 33.3" (3300mm x 820mm)

- Table Load Capacity

- 6600 lbs (3000 kg)

Feed Rate

- Rapid Traverse Rate X/Y

- 945 in/min (24 m/min)

- Rapid Traverse Rate Z

- 787 in/min (20 m/min)

- Cutting Feed (X/Y/Z)

- 393 in/min (10 m/min)

Spindle

- Spindle Power

- 101/40 HP

- Spindle Speed

- 12,000 rpm

- Spindle Taper

- CAT50

Tools

- Standard Number of Tools

- 40

- Maximum Tool Weight

- 44 lbs (20 kg)

- Maximum Tool Length

- 13.8" (350 mm)

- Maximum Tool Diameter

- ø 3.9" (100 mm) / ø 7.9" (200 mm) without adjacent tool

- Tool Changing Time- Tool to Tool

- 2.5 sec (Speed is changeable for heavy-weight tools)

General

- Machine Weight

- 55,000 lbs (25,000 kg)

- Machine Control

- FANUC F30i‐B5