Machines

DIE & MOLD MACHINING EQUIPMENT

Browse By Type

More Than The

World's Best Machines

Results

Bottom-line Results

and Long-Term Relationships

Multi-axis CNC machines from the world’s leading machine builders, combined with Methods’ application engineering and integration, maximize your production output and the quality of die and mold manufacturing results. The precision and versatility of our solutions enable your shop to produce one mold or replicate the job for multiple clones.

An increasing reliance on injection-molded plastics goes far beyond packaging, toys and simple consumer products.

Today, precision-manufactured plastics are incorporated in components engineered for automotive, aerospace, medical devices and other demanding industries.

Our application engineers custom design and optimize your CNC machining solution to ensure Methods machines deliver the greatest geometric precision, multi-axis capabilities, cutting accuracy, positioning accuracy, repeated positioning accuracy, and interpolation accuracy with the highest speed.

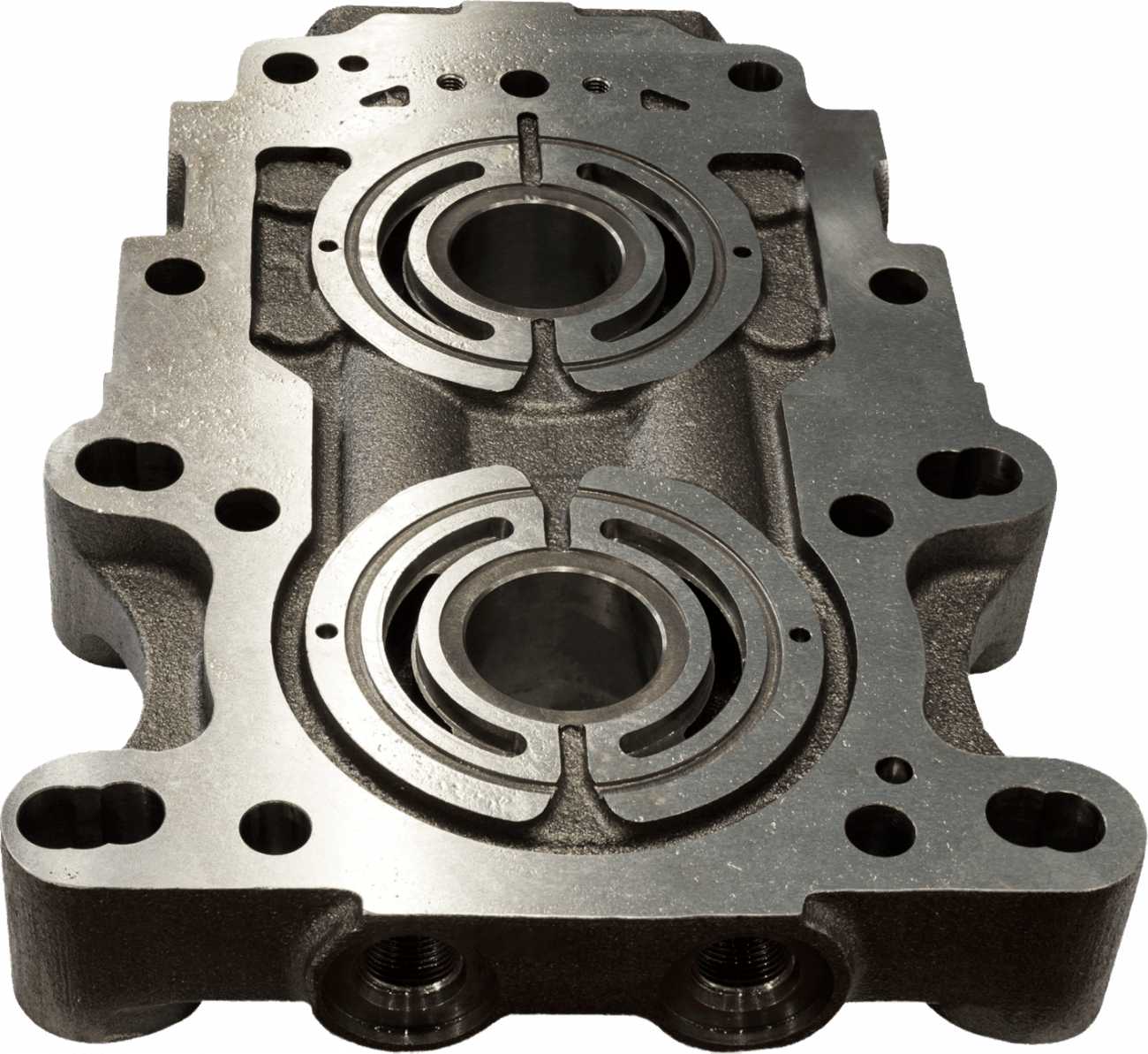

Machine Any Die & Mold Components

- Mold Inserts

- Switch Components

- Stamping Die Inserts

- Gears and Ratchets

- Trim Sections

- Threaded Parts

- Housings and Covers

- Die Punches

Proven Experts

Time Tested

and Industry Trusted

Methods engineering teams and automation experts design systems that previously required multiple machines and operators. The reliability is unparalleled and the machine builds are rugged and substantial, further adding to high-precision results.

Customers rely on best-in-class CNC machines from Methods to meet the die/mold manufacturing industry’s high demands for both accuracy and speed. Within the die mold sector, over 5,000 of our machines are installed across the U.S., Canada, and Mexico.