51

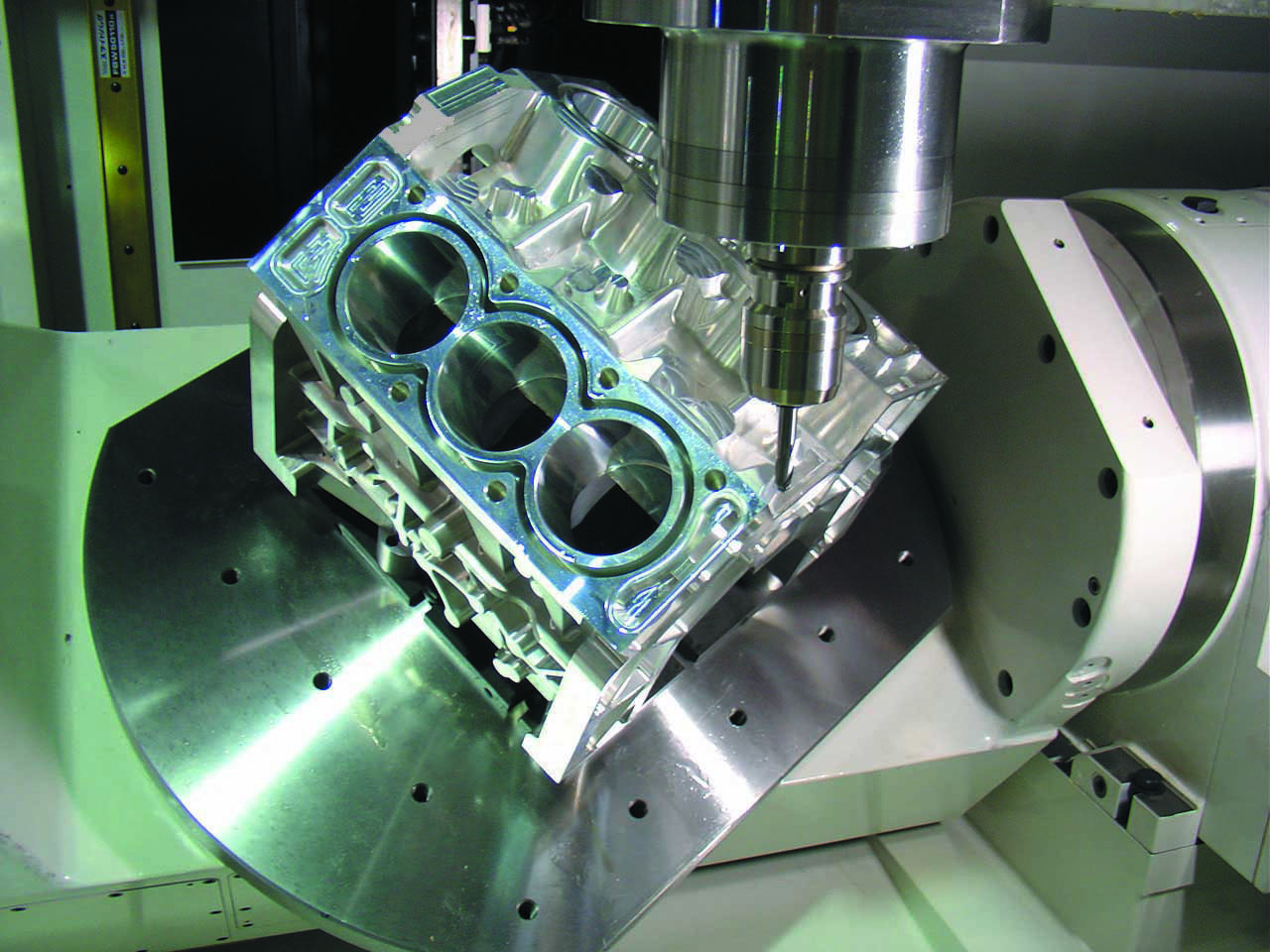

OKK

VP9000-5AX

Request Information

Or call 1-877-668-4262

Product Details

Features & Benefits

- highly rigid cross roller linear guides

- double-anchoring type ball screws

- Coolant through spindle preparation

- Coil-type chip conveyors

- Excellent Chip Disposal, accessibility with compact-sized machine

- Space saving design for economical use of floor space

Technical Data

Travel

- X-Axis Travel

- 32.3" (820mm)

- Y-Axis Travel

- 40.2" (1020mm)

- Z-Axis Travel

- 22.1" (560mm)

- A-Axis Travel

- ‐120° to +30°

- C-Axis Travel

- 360°

- Table Top to Spindle Nose

- 9.84" - 31.80" (250mm - 810mm)

Table

- Table Work Surface Area

- ø 31.5" x 24.8" (800mm x 630mm)

- Table Load Capacity

- 1100 lbs (500 kg)

Feed Rate

- Rapid Traverse Rate (X/Y/Z)

- 1,260 in/min (32 m/min)

- Cutting Feed (X/Y/Z)

- 1,260 in/min (32 m/min)

Spindle

- Spindle Power

- 50/25 HP

- Spindle Speed

- 12,000 rpm

- Spindle Taper

- CAT40

Tools

- Standard Number of Tools

- 60 (80/120)

- Maximum Tool Weight

- 15.4 lbs (7 kg)

- Maximum Tool Length

- 11.8" (300 mm)

- Maximum Tool Diameter

- ø 4.92" (125 mm)

- Tool Changing Time- Tool to Tool

- 3.2 sec

General

- Machine Weight

- 39,700 lbs (18,045 kg)

- Machine Control

- FANUC F31i-B5

Videos

Sorry, there are no videos for this machine.