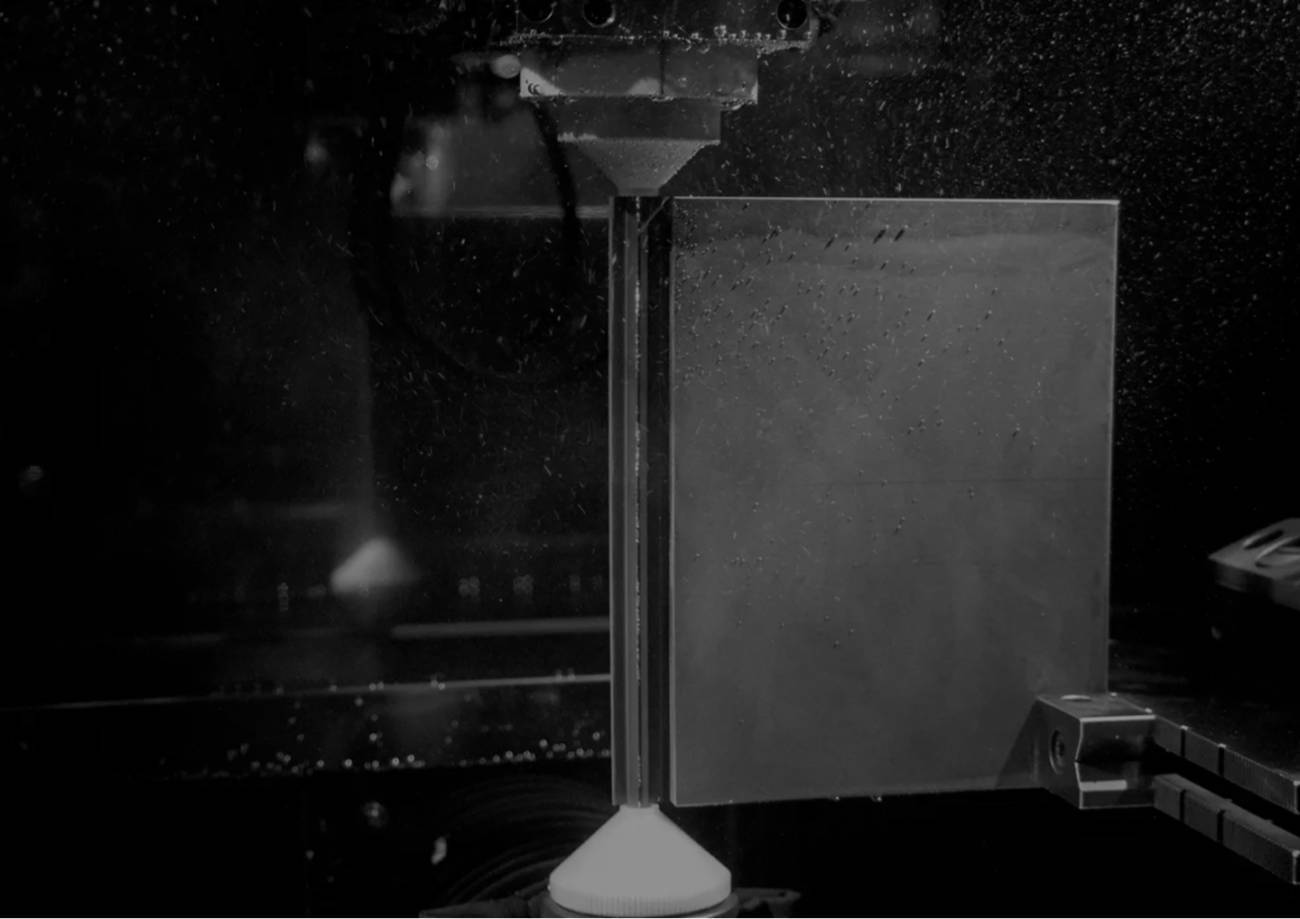

Electrical Discharge Machining (EDM)

Our EDM machines offer precision and high durability to deliver the throughput you need to achieve your ROI.

EDM Machines

Our EDM machines offer precision and high durability to deliver the throughput you need to achieve your ROI.