51

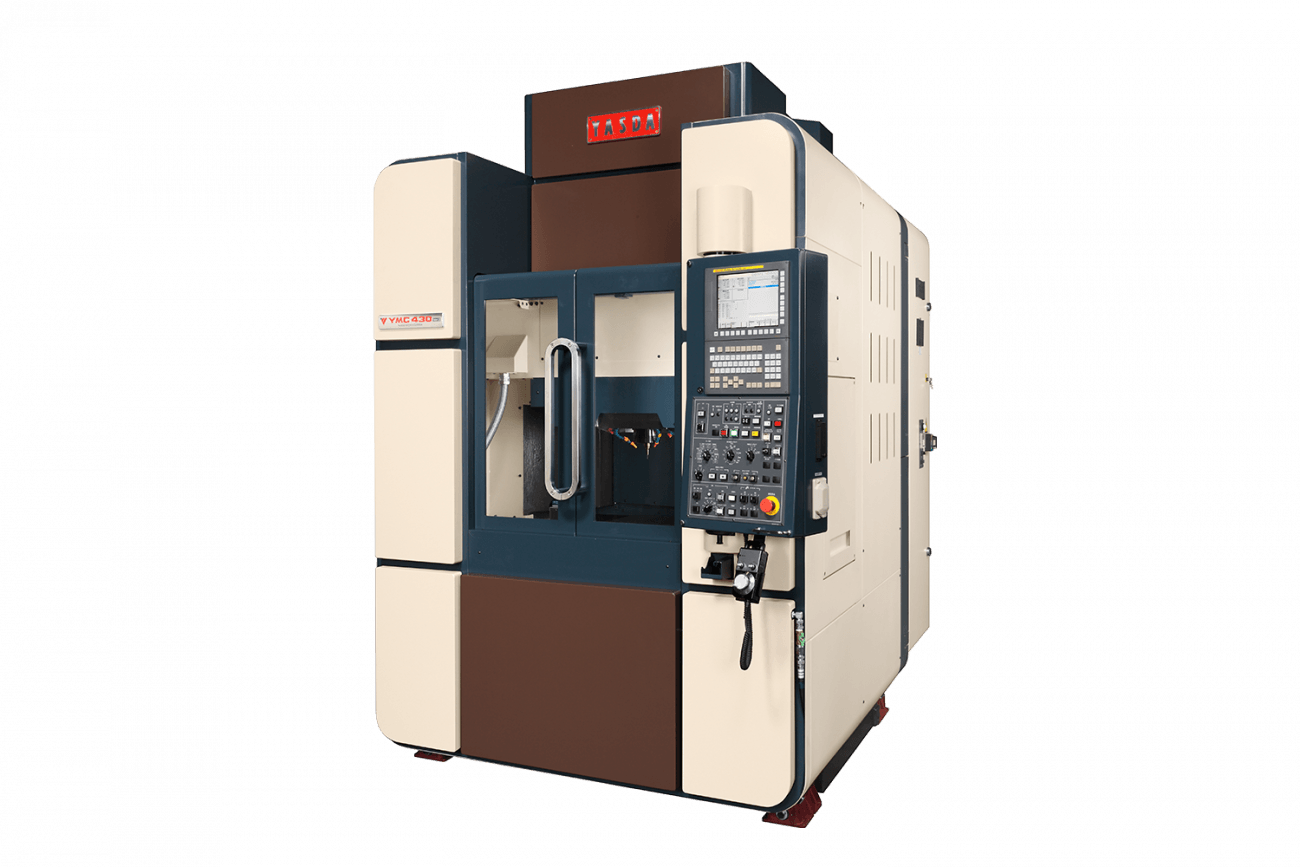

Yasda

YMC430 RT10

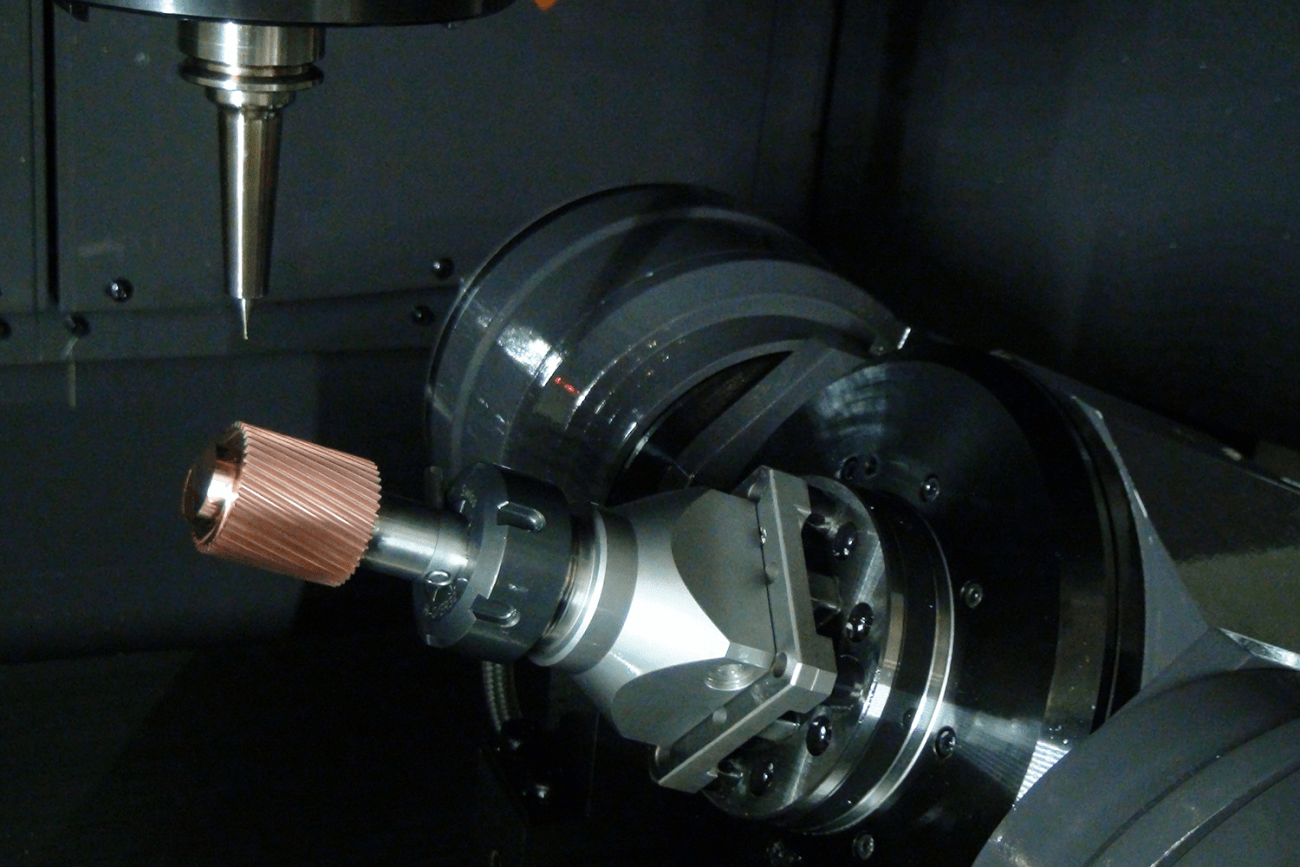

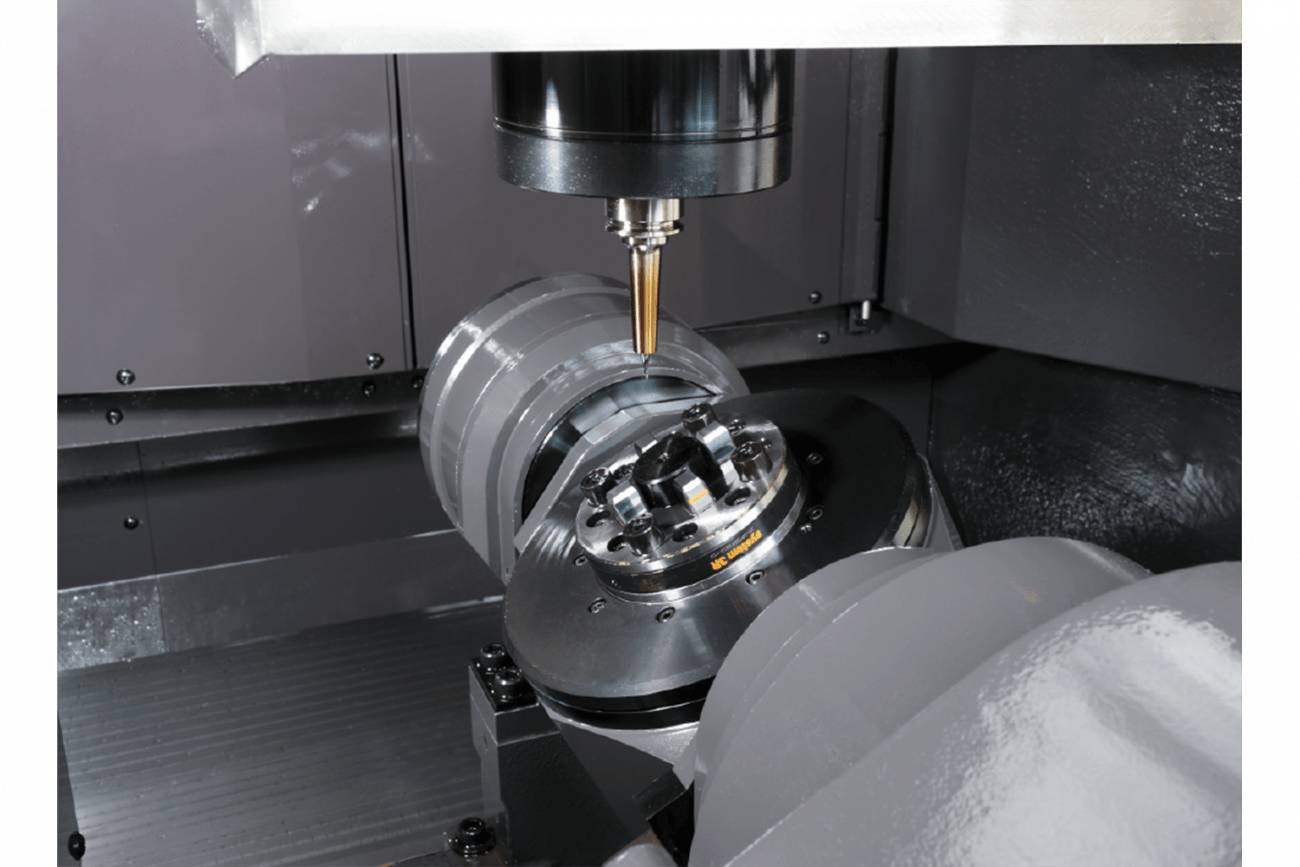

The Yasda YMC430, high precision machining center is integrated with a high precision rotary tilting table with direct drive motors. This combination allows the machining of precise multiple face indexing in one set up, and 5-axis simultaneous micro machining of complex parts.

Request Information

Or call 1-877-668-4262

Product Details

Features & Benefits

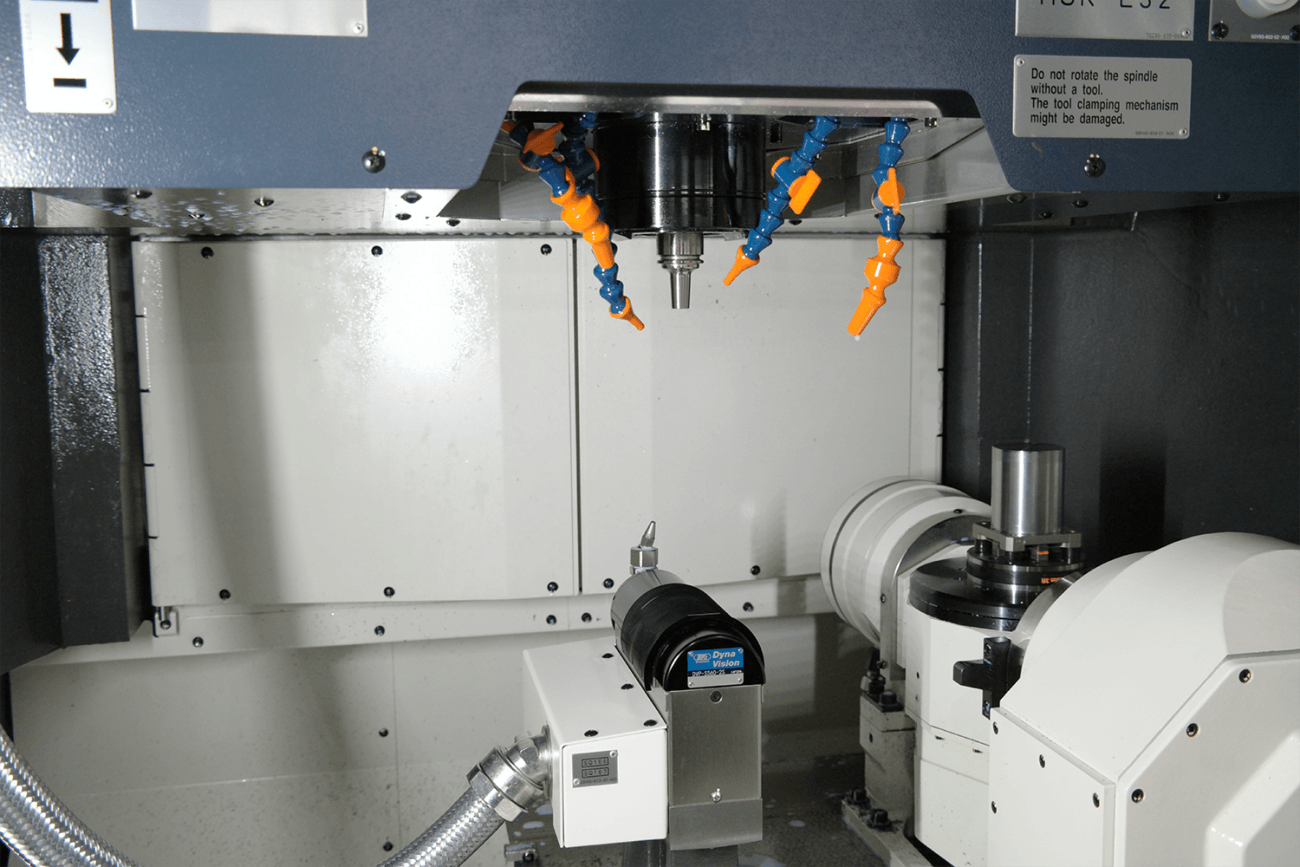

- X/Y/Z Axis Controlled by High Speed Linear Motors

- Symmetrical H-shaped Column

- Spindle Head Symmetrical Longitudinally and Horizontally

- Raised Bed Sides for Increased Rigidity

- Low Centroid X/Y Table

- Ultra Precision Linear Guides

- High Precision Positioning

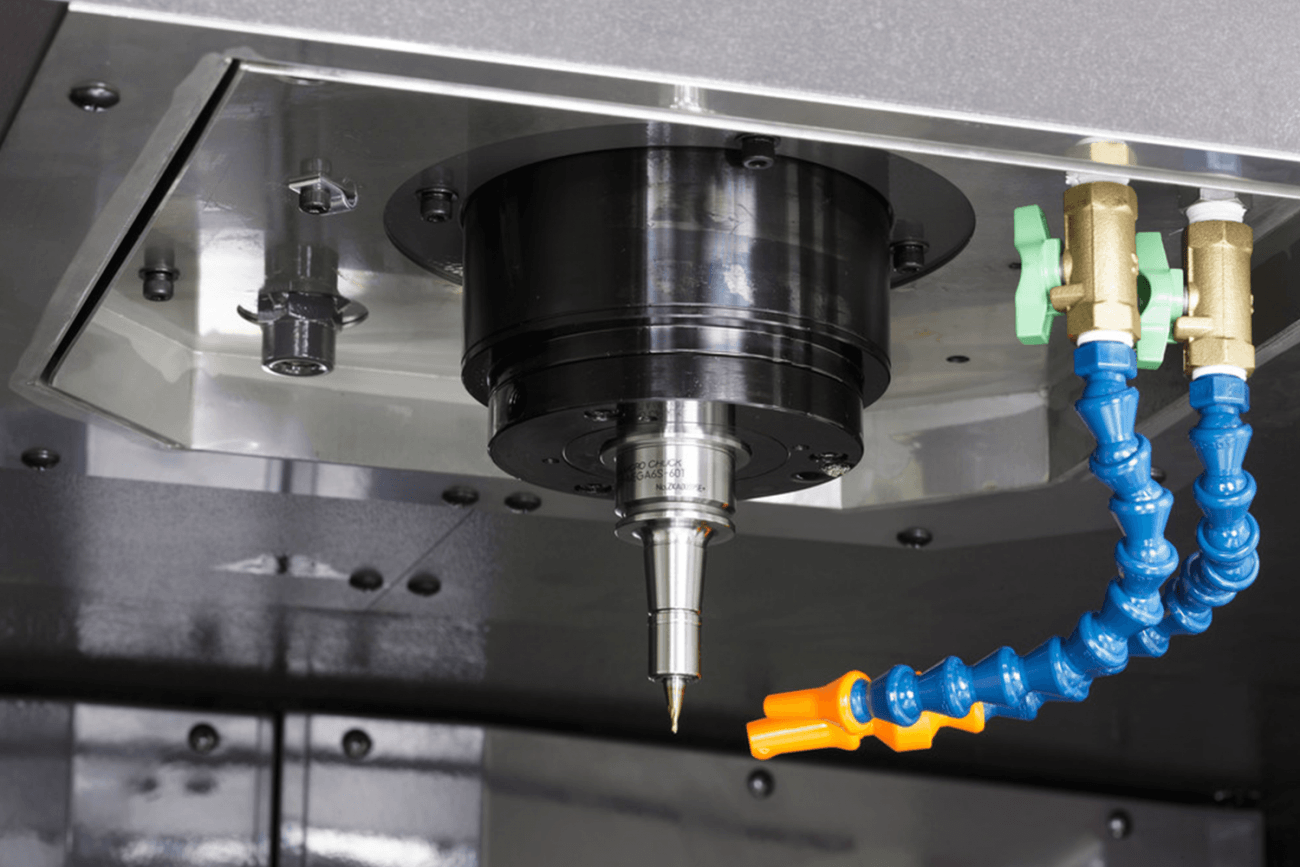

- Large Capacity HSK-E32 Spindle Taper

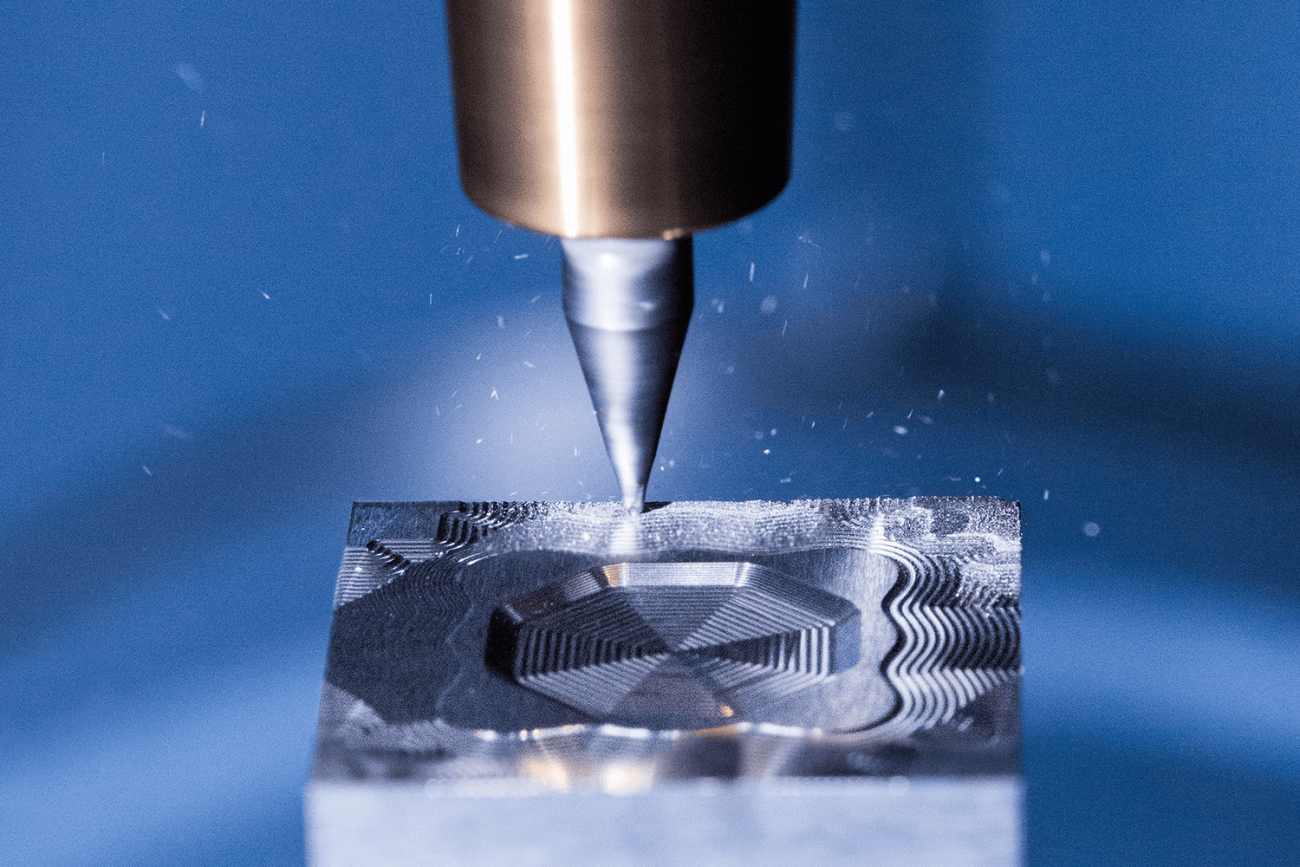

- Superior Part Surface Finishes

- Positioning Accuracy +/- 1μm

- Thermal Distortion Stabilizing System for Sustaining High-precision Machining

- High Speed Positioning

- Large Cutting Tool Capacity

Technical Data

Travel

- X-Axis Travel

- 16.5 (420) in (mm)

- Y-Axis Travel

- 11.8 (300) in (mm)

- Z-Axis Travel

- 9.8 (250) in (mm)

- B-Axis (tilt table)

- +100 to -10 degrees

- C-Axis (rotary table)

- 360º (0.0001º)

Feed Rate

- X, Y, and Z Rapid Traverse

- 20,000 mm/min (787ipm)

- B-Axis (tilt) Rapid Traverse

- 100 rpm with DD motors

- C-Axis (rotary) Rapid Traverse

- 200 rpm with DD motors

- X, Y and Z Axes Cutting Feed Rate

- Max. 12,000 mm/min (472ipm) with HAS

- B-Axis (tilt) Cutting Feed Rate

- 40 rpm with HAS

- C-Axis (rotary) Cutting Feed Rate

- 40 rpm with HAS

Table

- Table Working Surface

- 23.6x13.8 (600x350) in (mm)

- Table Loading Capacity

- 33 (15) lbs (kg)

Spindle

- Spindle Type

- Self adjusting pre-load

- Spindle Speed Range

- 200-40000 rpm (opt)

- Spindle Taper

- E-32 -

Tooling

- Maximum Tool Weight

- 1.1 lbs (500g)

- Number of Tools

- 32 (90) std (opt)

General

- Machine Control

- FANUC 31i-B5 -