51

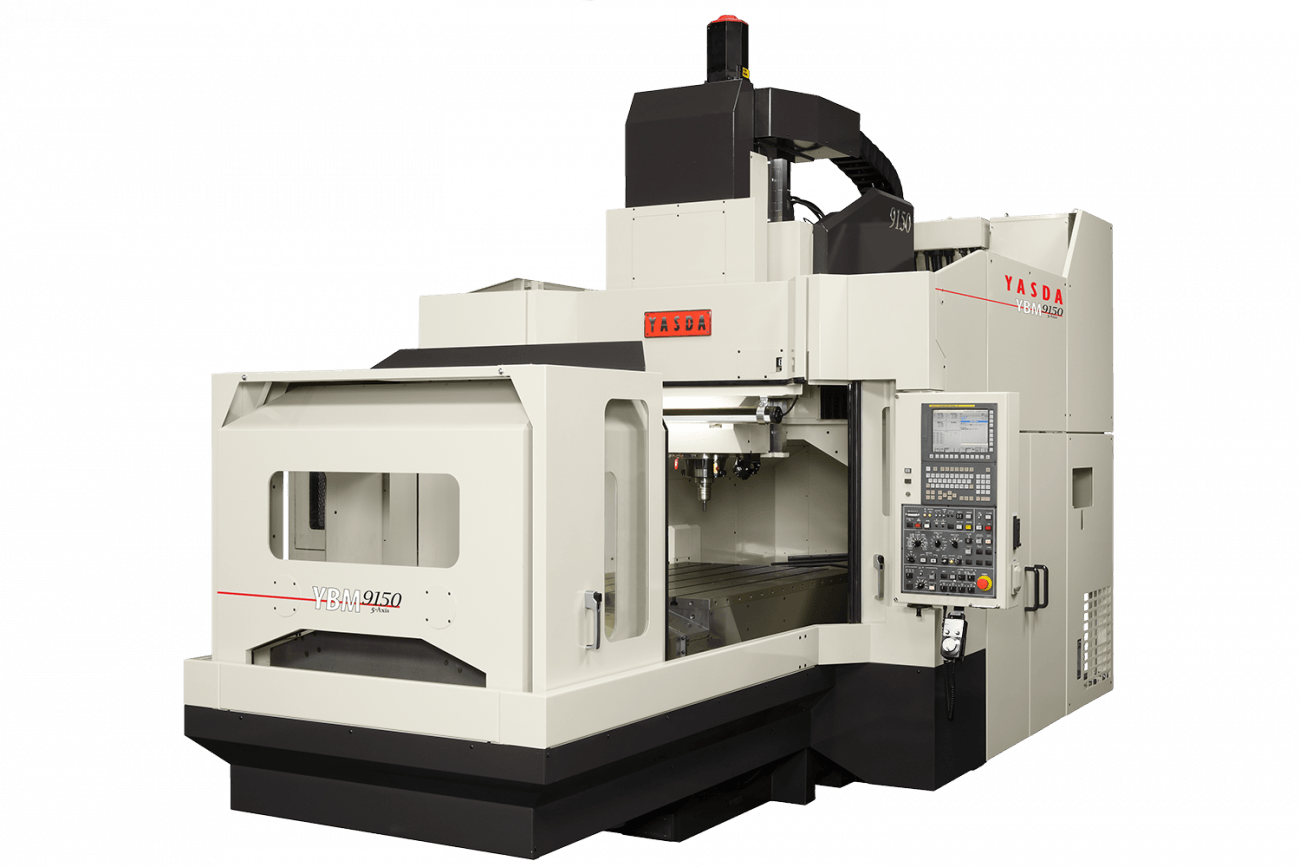

Yasda

YBM 9150V

The YASDA CNC Jig Borer and Vertical Machining Center YBM-9150V was developed with the purpose of machining large-sized mold bases and die set plates at high speed and high accuracy attained through the lightweight of movable bodies on the top beam such as a spindle housing and saddle and also the improvement in rigidity by integrating the column and top beam. Also, the axis stroke and workpiece loading capacity are increased.

Request Information

Or call 1-877-668-4262

Product Details

Features & Benefits

- Direct Drive Self-adjusting Spindle Preload

- Through Hardened (HR60) Box Guide Ways

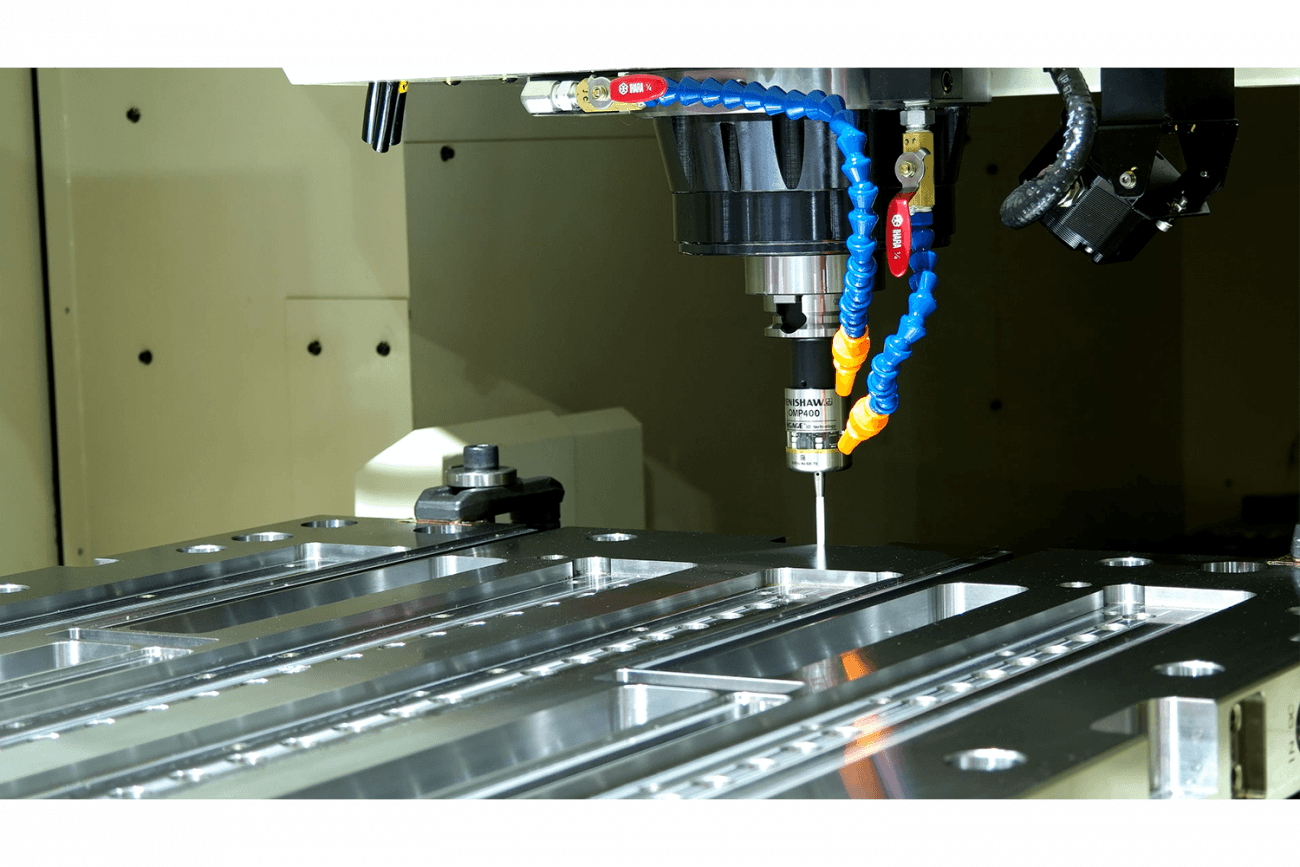

- Optical Scale Feedback on XYZ Axis

- Symmetrical Bridge Structure

- 3 Point Machine Base

- Thermal Distortion Stabilization

- Space Saving Footprint

- Curvic Coupling for Pallet Clamping

- Rigid Machine Structure for machining Various Material Types

- Optical Scale Feedback for Precise Positioning

- Probing Systems

Technical Data

Travel

- X-Axis Travel

- 59 (1500) in (mm)

- Y-Axis Travel

- 35.4 (900) in (mm)

- Z-Axis Travel

- 17.7 (450) in (mm)

- Distance from Table Surface to Spindle

- 5.9-23.6 (150-600) in (mm)

Feed Rate

- Rapid Traverse

- 787 (20) in/min (m/min)

- Feed Rate

- 196 (5000) in/min (mm/min)

Table

- Table Working Surface

- 59x35.4 (1500x900) in (mm)

- Table Loading Capacity

- 6615 (3000) lbs (kg)

Spindle

- Spindle Type

- Self adjusting Pre-load -

- Spindle Speed Range

- 100-24000 (150-30000) rpm (opt)

- Spindle Taper

- 7/24 taper No. 40 (HS Optional) -

Tooling

- Number of Tools

- 60 (100) std (opt)

- Maximum Tool Weight

- 15.5 (7) lbs (kg)

- Maximum Tool Length

- 9.8 (250) in (mm)

- Maximum Tool Diameter

- ø 3.9 (100) in (mm)

General

- Machine Weight

- 35274 (16000) lbs (kg)

- Machine Control

- Fanuc 31I-B5-10.4" Color LCD -