51

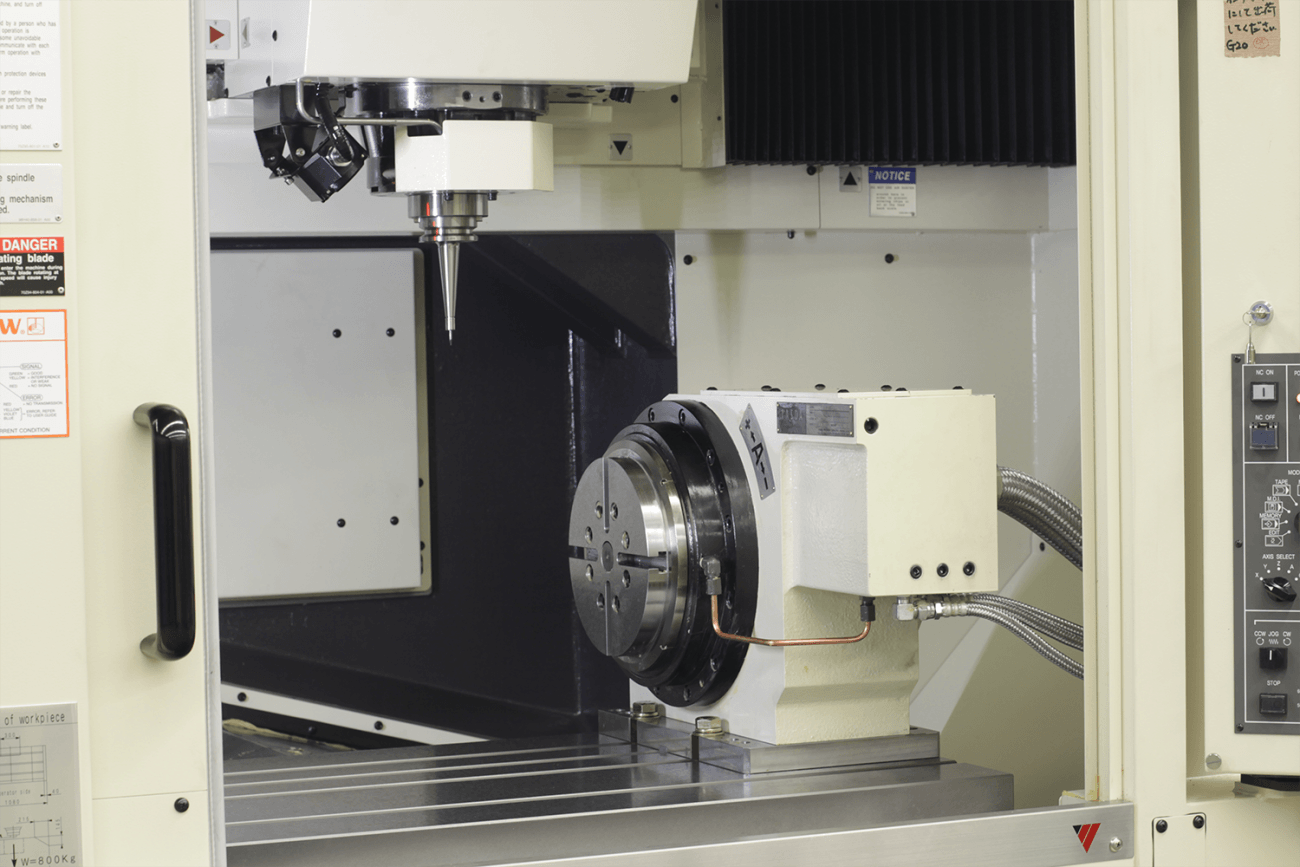

Yasda

YBM-950V

The YASDA CNC Jig Borer YBM-950V is based on the highly successful YBM-850V, known for its high-speed/high accuracy machining of small parts including mold and die parts requiring high-precision contour machining. The YBM-950V takes the next step with its compact and high-efficient design developed to dominate the high-precision machining field.

Product Details

Features & Benefits

- Direct Drive Self-adjusting Spindle Preload

- Through Hardened (HR60) Box Guide Ways

- Optical Scale Feedback on X/Y/Z Axis

- Symmetrical Bridge Structure

- 3 Point Machine Base

- Thermal Distortion Stabilization

- Space Saving Footprint

- Curvic Coupling for Pallet Clamping

- Rigid Machine Structure for Machining Various Material Types

- Optical Scale Feedback for Precise Positioning

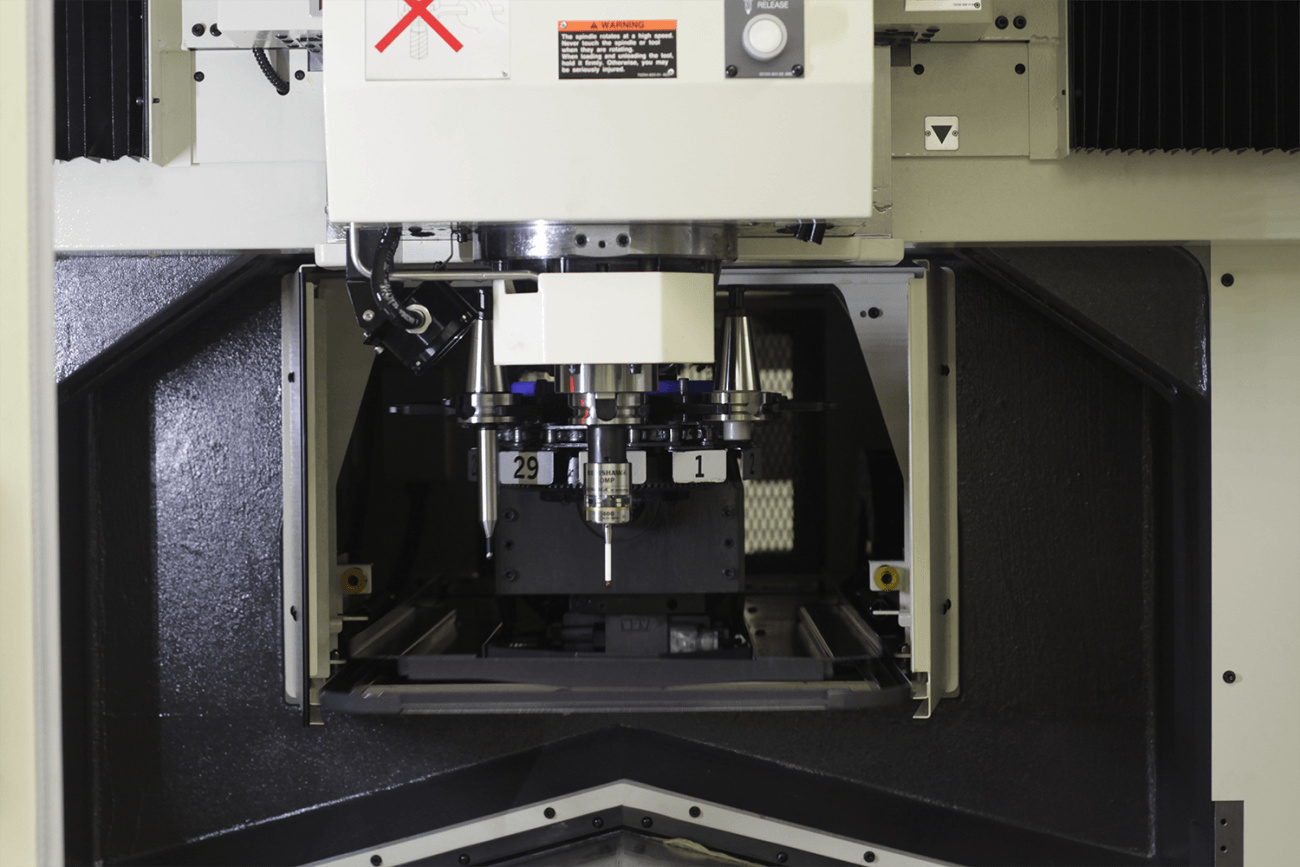

- Probing Systems

Technical Data

Travel

- X-Axis Travel

- 35.4 (900) in (mm)

- Y-Axis Travel

- 19.7 (500) in (mm)

- Z-Axis Travel

- 13.8 (350) in (mm)

- Distance from Table Surface to Spindle

- 7.9-2.7 (200-550) in (mm)

Feed Rate

- Rapid Traverse

- 787 (20) in/min (m/min)

- Feedrate

- 196 (5000) in/min (mm/min)

Table

- Table Working Surface

- 39.4x19.7 (1000x500) in (mm)

Spindle

- Spindle Type

- Self-adjusting Pre-load

- Spindle Speed Range

- 100-24000 (150-30000) rpm (opt)

- Spindle Taper

- 7/24 taper No. 40

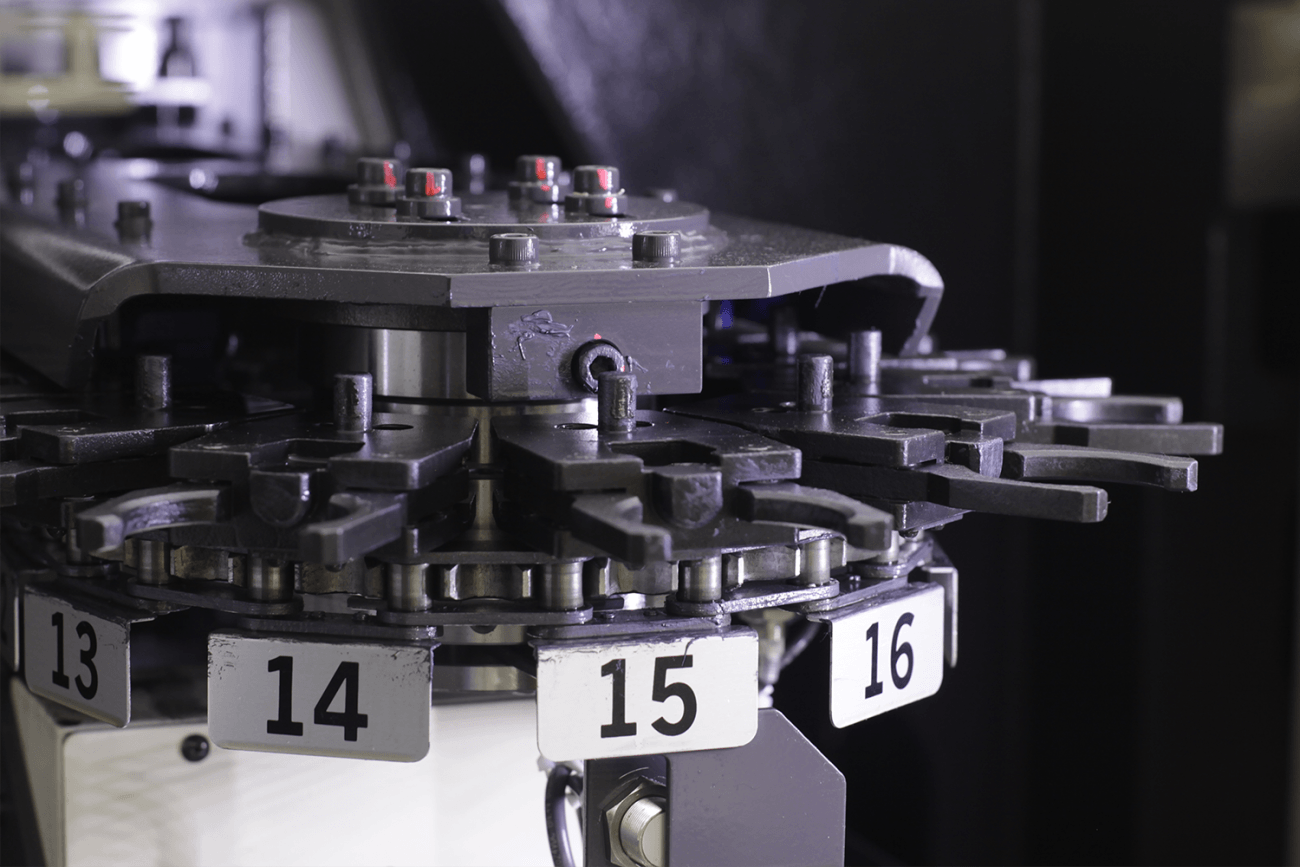

Tooling

- Number of Tools

- 30 (40/60/90) std (opt)

- Maximum Tool Weight

- 15.5 (7) lbs (kg)

- Maximum Tool Length

- 9.8 (250) in (mm)

- Maximum Tool Diameter

- ø 3.9 (100) in (mm)

General

- Machine Weight

- 24250 (11000) lbs (kg)

- Machine Control

- Fanuc 31I-B5-10.4" Color LCD -

Videos

Sorry, there are no videos for this machine.