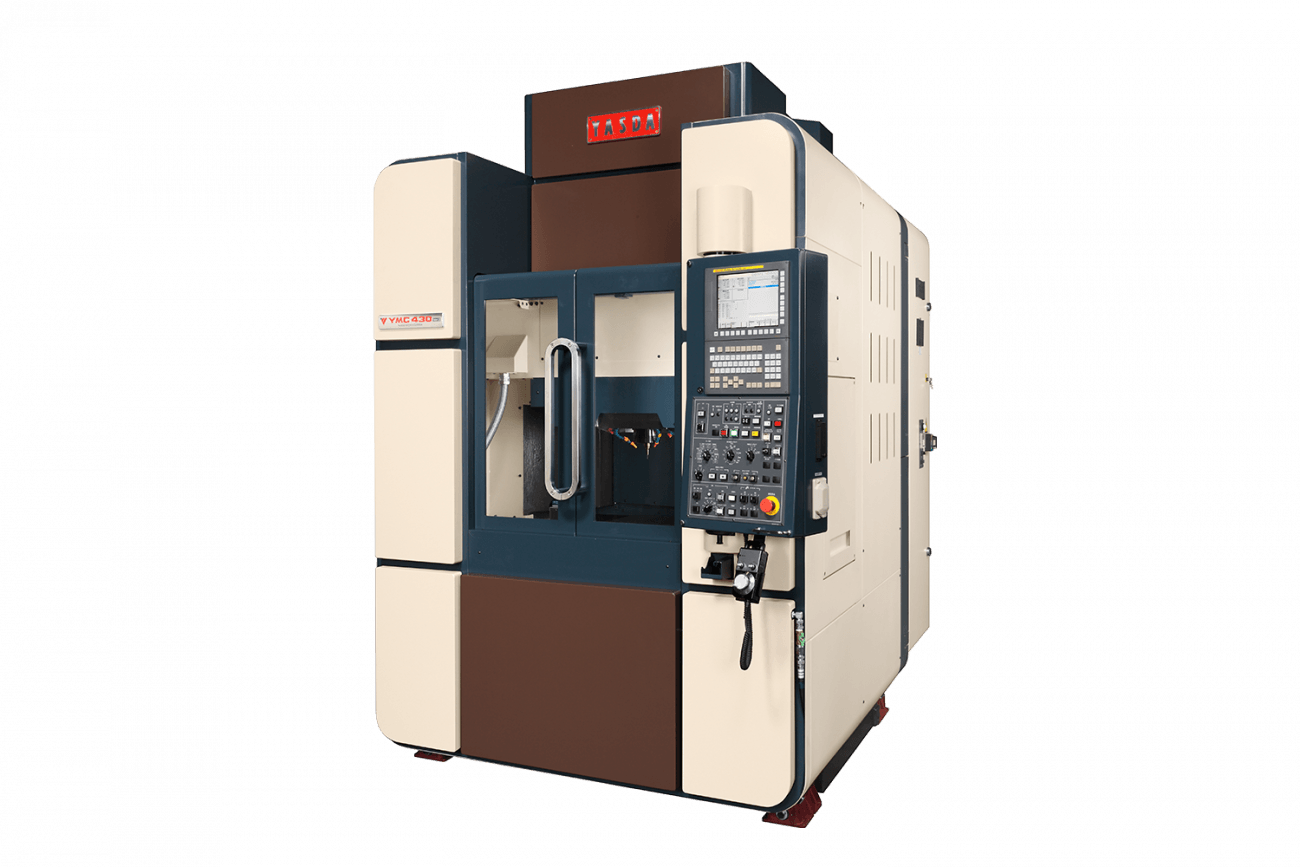

Yasda

YMC430

YASDA Micro Center YMC430 is a state-of-the-art high-end machine, which fits the rapidly increasing demands for ultra-precision and high surface quality milling in the fields of medical equipment parts, IT related parts, high precision miniature die and mold etc., where the technologies are constantly advancing. All controlled axes (X, Y and Z) driven by high speed linear motors, highly rigid symmetric frame design and a unique thermal distortion stabilizing system which sustains machining accuracy in long cycle time operation, will assure unsurpassed high accuracy and excellent motion performance in various applications. YMC430 provides the best solution for future demands for ultra-precision and high surface quality machining.

Product Details

Features & Benefits

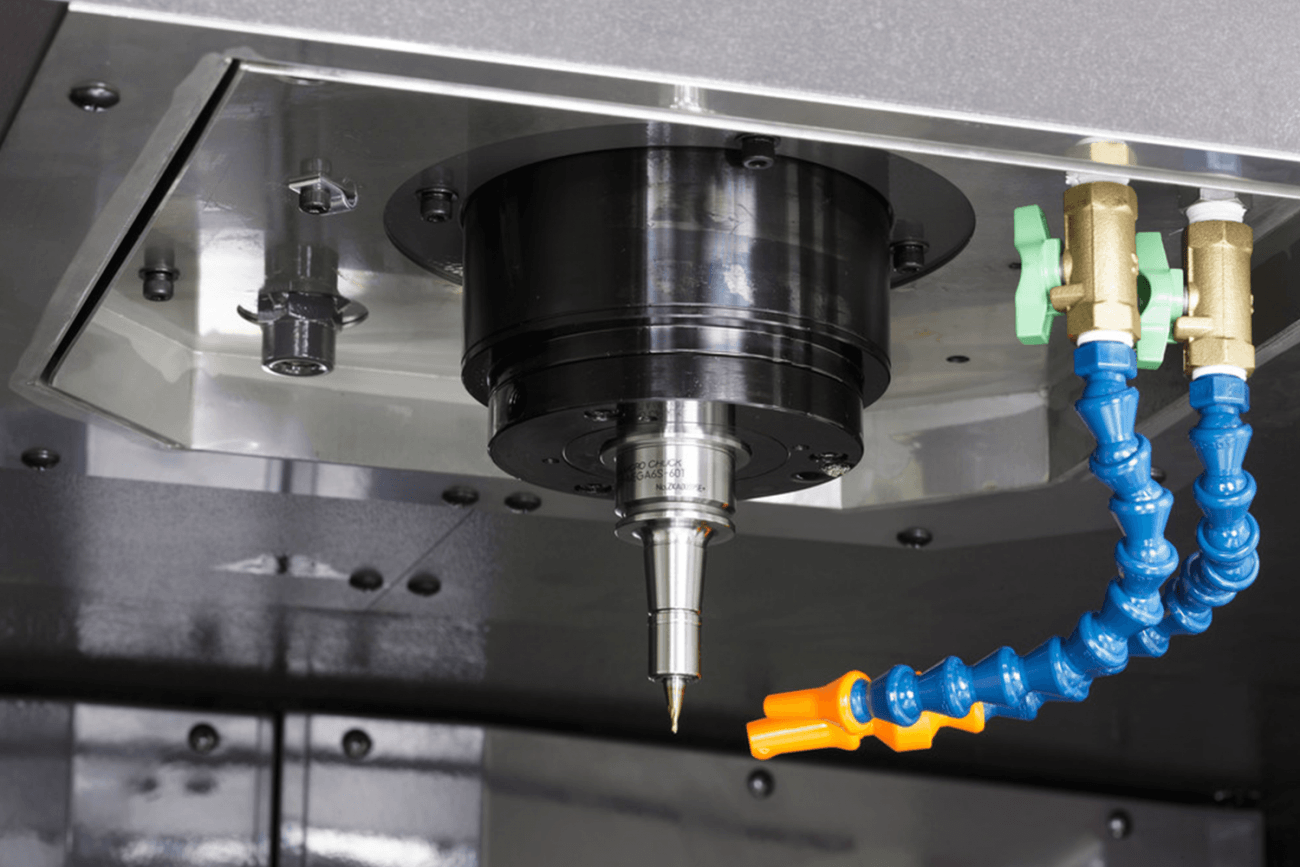

- XYZ Axis Controlled by High Speed Linear Motors

- Symmetrical H-shaped Column

- Spindle Head Symmetrical Longitudinally and Horizontally

- Raised Bed Sides for Increased Rigidity

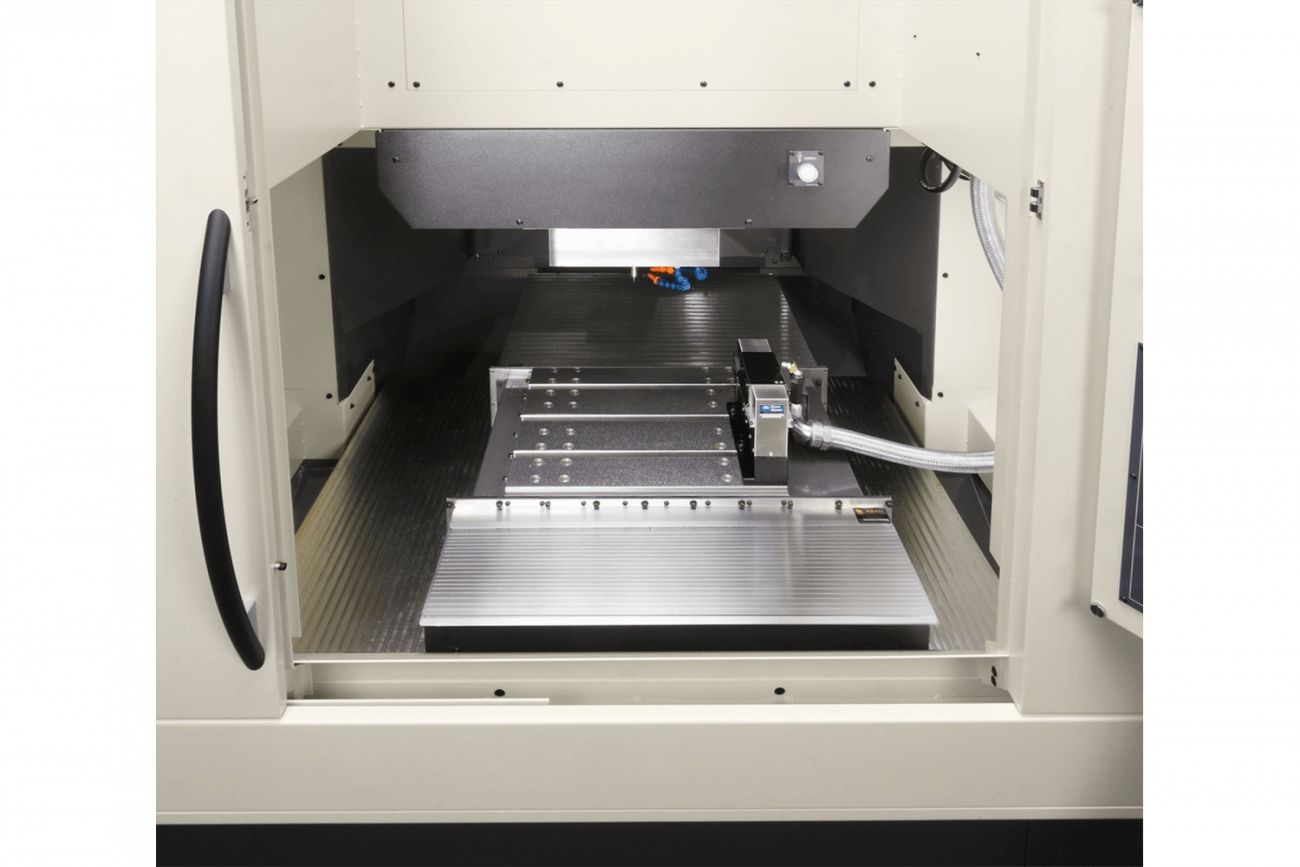

- Low Centroid X-Y Table

- Ultra Precision Linear Guides

- High Precision Positioning

- Large Capacity HSKE32 Spindle Taper

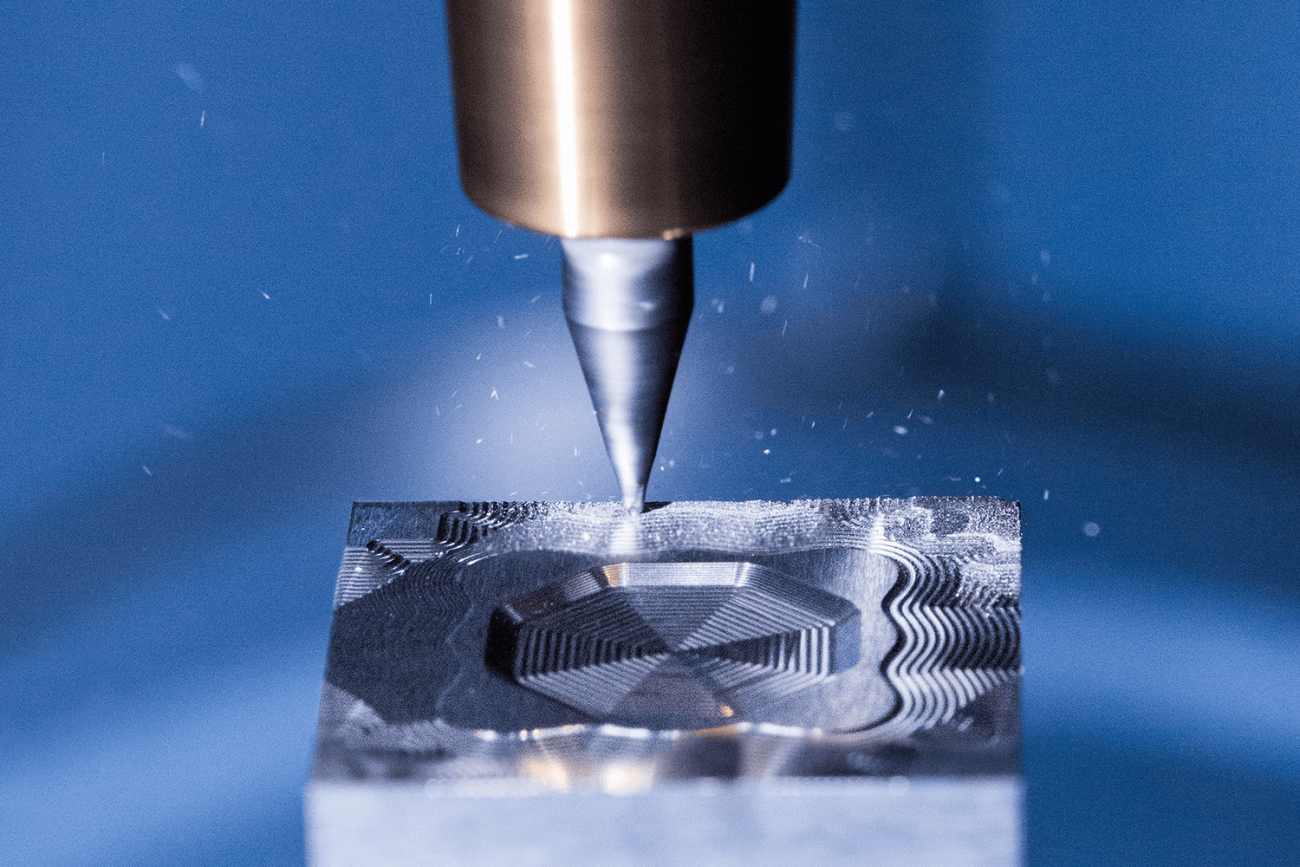

- High Quality Surface Finishes

- Positioning Accuracy +/- 1μm

- Thermal Distortion Stabilizing System for Sustaining High-precision Machining

- High Speed Positioning

- Large Cutting Tool Capacity

Technical Data

Travel

- X-Axis Travel

- 16.5 (420) in (mm)

- Y-Axis Travel

- 11.8 (300) in (mm)

- Z-Axis Travel

- 9.8 (250) in (mm)

- Distance from Table Surface to Spindle

- 5.9-15.8 (150-400) in (mm)

Feed Rate

- Rapid Traverse

- 788 (20) in/min (m/min)

Table

- Table Working Surface

- 23.6x13.8 (600x350) in (mm)

- Table Loading Capacity

- 221 (100) lbs (kg)

Spindle

- Spindle Speed Range

- 200-40000 rpm (opt)

- Spindle Taper

- E-32 -

Tooling

- Number of Tools

- 32 (90) std (opt)

General

- Machine Control

- FANUC 31i-B5 -