51

Kiwa

Triple H40 3-Axis

KIWA Triple H40 series, is a high-performance horizontal machining center with a Column Traverse Design. This allows for heavy parts to be machined in a compact space. The machine design will accommodate a variety of workpieces and factory automation equipment. The machine is equipped with a wide center trough in the machining area and a chip auger to carry chips directly down the center trough for disposal at the rear of the machine.

Product Details

Features & Benefits

- (4) Simultaneously controlled axes (4+1)

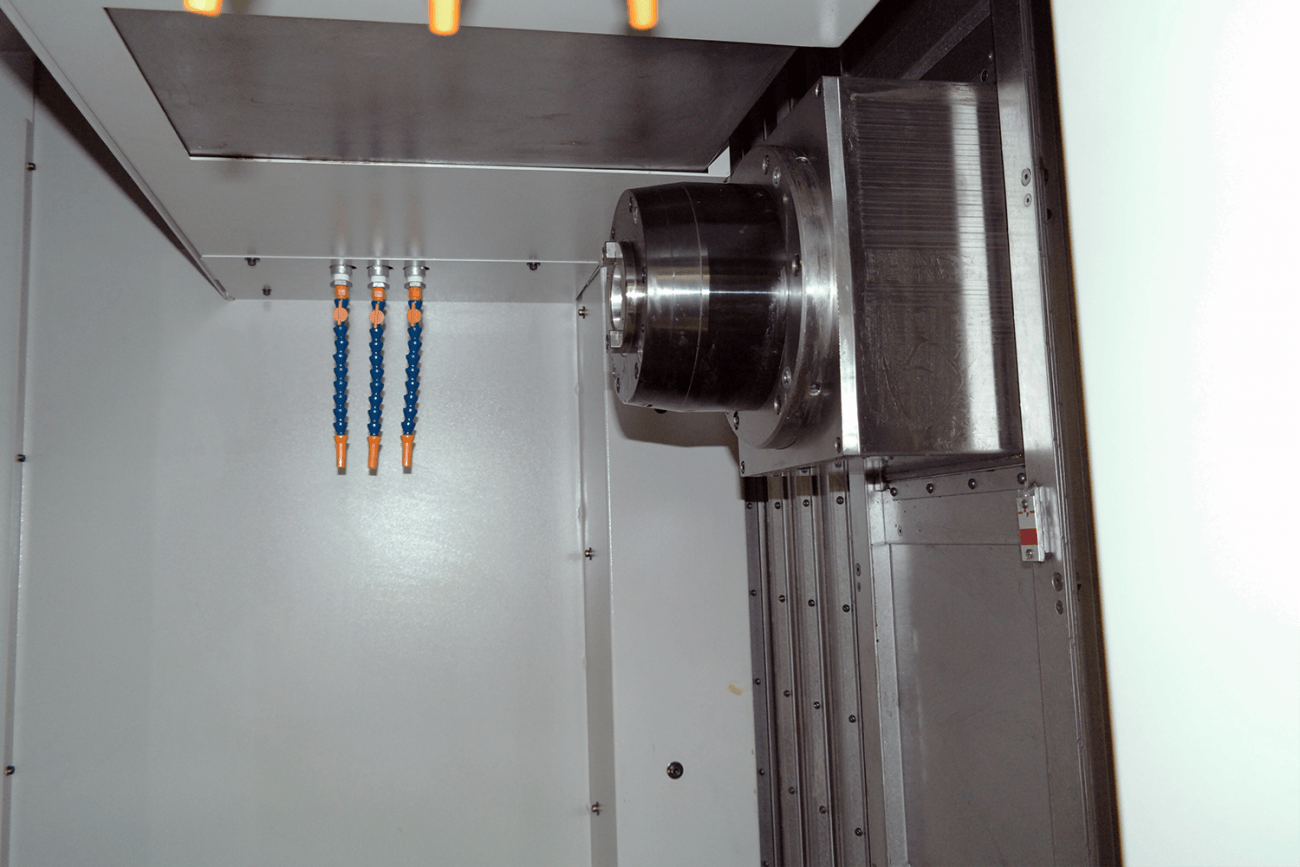

- Provision for coolant through spindle

- Overhead Coolant chip flow system

- Spindle oil cooler

- Chip Auger and Chip conveyor std

- Tool life management

- AICC1

- 1280 meter / 512 kB memory

- Helical interpolation

- 200 tool off sets

- Macro programming

Technical Data

Travel

- X-Axis Travel

- 20.1 (510) in (mm)

- Y-Axis Travel

- 20.1 (510) in (mm)

- Z-Axis Travel

- 15.7 (400) in (mm)

Pallet

- Pallet Surface to Spindle Center

- 12.2 - 32.3 (310-820) in (mm)

- Pallet Center to Spindle Nose

- 2.8 -18.5 (70-470) in (mm)

- Pallet Load Capacity

- 2,200 (1000) lbs (kg)

- Max. Workpiece Size

- 32.3 x 17.7 (820 x 450) in (mm)

Feed Rate

- X-Axis Rapid Traverse

- 2362 (60) in (m)

- Y-Axis Rapid Traverse

- 2362 (60) in (m)

- Z-Axis Rapid Traverse

- 2362 (60) in (m)

- Cutting Feed (X/Y/Z)

- 1,181 (30) in (m)

Spindle

- Spindle Power

- 20 HP

- Spindle Speed

- 12000 rpm (opt)

- Spindle Taper

- Cat 40

Tools

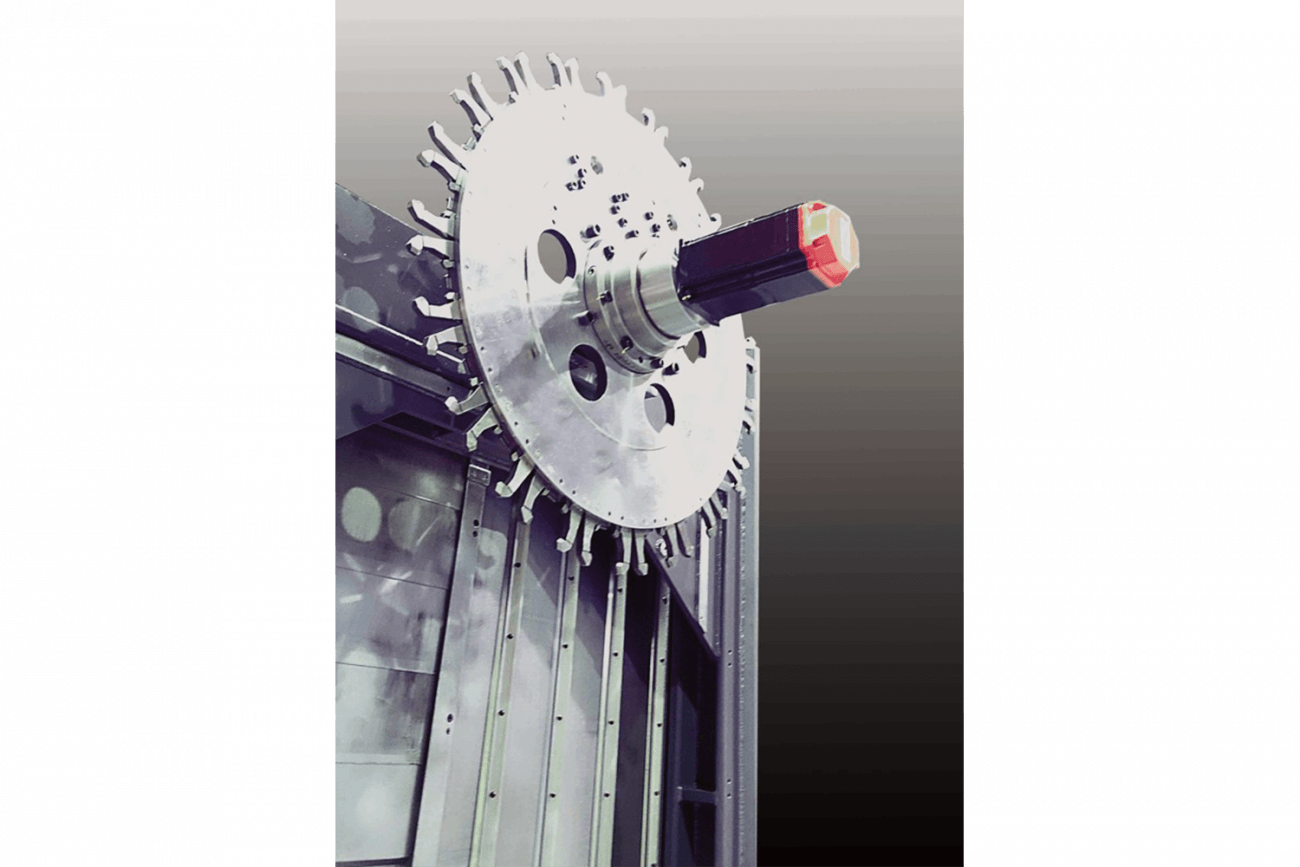

- Standard Number of Tools

- 40 std (opt)

- Maximum Tool Weight

- 17.6 (8) lbs (kg)

- Maximum Tool Length

- 11.8 (300) in (mm)

- Maximum Tool Diameter

- 3.5 (90) in (mm)

- Maximum Tool Diameter- No Adjacent Tool

- 7.1 (180) in (mm)

- Tool Changing Time- Tool to Tool

- 4.5 sec

General

- Coolant Tank Capacity

- 119 (450) gal (L)

- Machine Weight

- 12,600 (5,700) lbs (kg)

- Machine Control

- 0iMF